Our History

Take a look at this page covering some of the most important developments in InfraTec's company history.

2024

InfraTec completes the extension of its headquarters (block 3) – the company's largest construction project so far, with an investment of 20 million euros. The energy-efficient building, constructed according to KfW Efficiency House 55 standard, is equipped with a 100 kWp photovoltaic system that supplies the cleanroom with green electricity. With this project InfraTec has confirmed its decision for Dresden as a production and development location, which also offers potential for future expansion.

A total of 2,700 m² of office space as well as new, state-of-the-art laboratories and production areas for thermographic cameras and infrared detectors were built, including a cleanroom for growing DLaTGS crystals. The capacity for radiometric calibration of thermal imaging cameras has also been significantly expanded.

InfraTec introduces the DSV-7311high-performance detector, the first detector based on DLaTGS (deuterated L-alanine doped triglycine sulphate). The single-channel detector in a TO39 housing is the technical highlight of the new “PYRONEER” product series.

The DLaTGS detectors with an extremely thin precious metal black layer are unbeatable in their performance class and offer a uniformly high detector sensitivity over the entire spectral range.

InfraTec is expanding the PYROMID® series with the LIM-082 in a TO39 housing. The new multi-channel detector for gas analysis combines two technologies in one miniaturised design for the first time: beam splitter and operational amplifier. With the LIM-082, which is insensitive to interference coupling, minimal gas concentrations can be precisely measured with fast response times.

With the PyrIQ® Evaluation Kit, InfraTec simplifies the initial testing of the digital pyroelectric detectors of the PyrIQ® series. Customers can use it for quick and easy testing various functions and adjustable parameters of the digital detectors, without the otherwise necessary development of software, firmware and test circuits.

InfraTec presents the latest model in its compact camera series, the TarisIR® mini. The radiometrically calibrated infrared camera is designed for universal use. With the associated IRBIS® software it enables entry-level access into stationary thermography at an excellent price-performance ratio. The TarisIR® mini achieves a high image quality and exceptionally sharpness of detail in its camera segment.

InfraTec expands its portfolio with INDU-SCAN base, a flexible and cost-effective thermography automation solution for 24/7 use to monitor processes and objects. The easy-to-install system allows the integration of multiple thermographic cameras and flexible configuration to meet the requirements of the measuring task.

INDU-SCAN base enables the continuous thermographic measurement of temperatures and the monitoring of production processes for the early detection of fault sources.

InfraTec equips its ImageIR® 6300 Z with the latest electronics, which allows the direct embedding of an operating system in the zoom infrared camera (embedded system). The integrated Software Development Kit (SDK) enables, among other things, the independent operation of the camera without a PC, the automated control of camera functions as well as the implementation of evaluation algorithms and camera control based on these algorithms directly in the camera.

Thanks to the autonomous operation made possible by the SDK functions, the ImageIR® 6300 Z can be used in hard-to-reach places. And the embedded SDK facilitates the easy integration into and adaptation to existing systems.

2023

InfraTec puts the DLaTGS crystal growth laboratory into operation. These crystals will be used in the newly developed PYRONEER detectors, which are characterised by a very good signal-to-noise ratio at extremely high modulation frequencies. By this they are considered the gold standard in Fourier transform infrared spectrometers (FTIR).

In addition to the growth of DLaTGS crystals, all further steps for manufacturing the high-performance detectors are also carried out in-house at InfraTec.

The high-speed infrared camera ImageIR® 8300 hs can capture extremely fast moving objects and highly dynamic thermal processes in full frame mode due to the new T2SLS detector with HOT Long-Life technology. The ImageIR® 8300 hs combines an image format of (640 x 512) IR pixels with a frame rate of 1,105 Hz and achieves an impressively high thermal resolution of 20 mK.

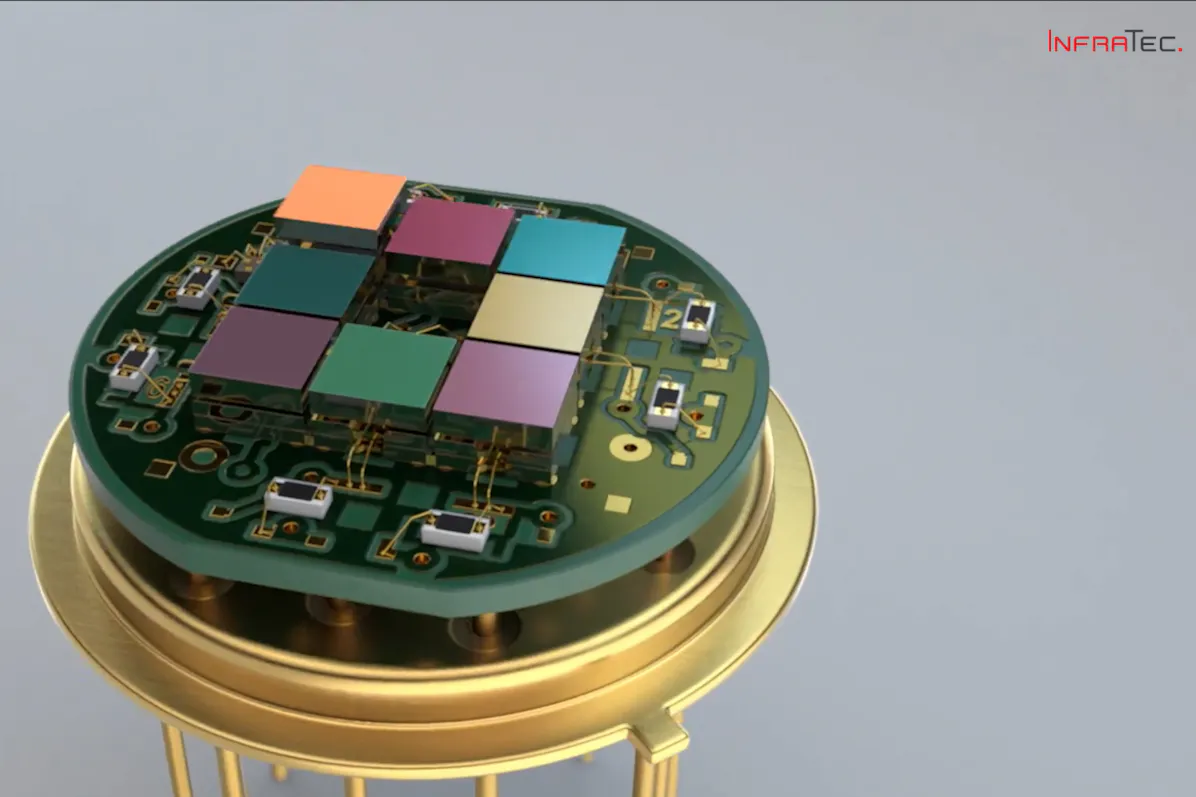

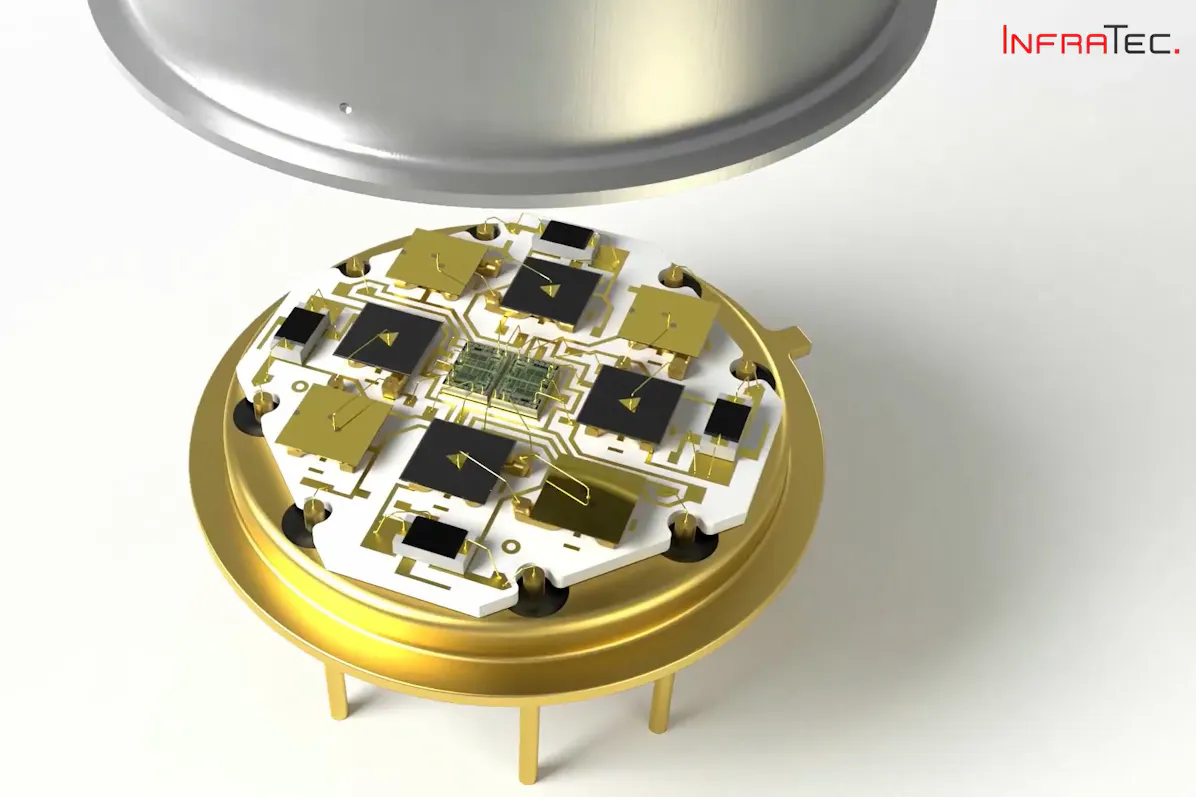

The innovative PYROMID® series from InfraTec is equipped with the pyroelectric detector LRM-292. The world's smallest multi-channel detector in a TO46 housing comes with integrated operational amplifier and thermal compensation and is predestined for measuring low gas concentrations with small measurement volumes.

2022

The excavators were also rolling at InfraTec in 2022. At the end of the year, the shell for the second extension complex was completed. The new complex has a total area of 2,700 m² and will provide spacious production and development areas for infrared cameras and pyroelectric detectors, as well as generously designed office space and social rooms. With an investment of 20 million euros, it is the Dresden-based company's largest construction project to date.

In 2022, three new thermal infrared cameras have been added to the camera series ImageIR®. With the SWIR cameras ImageIR® 8100 and ImageIR® 9100 for high temperature applications, InfraTec is expanding its portfolio in the short-wave infrared range. The compact, radiometrically calibrated ImageIR® 6300 Z, in turn, complements the range of powerful zoom thermal infrared cameras.

The sensor technology business unit has also received new additions. Already in 2021, InfraTec presented the digital detector PyrIQ with four spectral channels. Since 2022, this series also has a compensated 2-channel detector in the TO39 housing.

2021

InfraTec celebrates its 30th anniversary! In 1991 – with their enthusiasm for infrared – a group of young graduates of the Technical University of Dresden laid the foundation for InfraTec GmbH Infrarotsensorik und Messtechnik. In the past 30 years, InfraTec has developed into a globally recognised producer in the field of infrared technology. The two co-founders at that time, Dr. Matthias Heinze and Dr. Matthias Krauß, are still the managing directors of the company today with the two focal points sensor technology and infrared thermography.

Statements of our Customers

2020

The clean room and office building are inaugurated. InfraTec invested over 10 million euros in the expansion and modernisation of clean rooms for production and research as well as new office space. The new clean room houses a considerably enlarged, state-of-the-art machine park for the production of pyroelectric detectors. In the previous, modernised clean room building are the workplaces for manual production as well as the laboratories of the development department located.

During the corona pandemic, production at InfraTec was running at full speed. The demand for CO2 detectors for medical devices increased worldwide. As a company that supplies the corresponding components, InfraTec has worked through almost no corona-related restrictions in compliance with safety regulations.

In addition, the THERMAL-CHECK thermography system supports companies and public authorities in detecting people with elevated body temperature. Implementing such health protection measures serves among other things to secure public areas.

The ImageIR® 8300 hs – a new generation of high-speed infrared cameras – extends the ImageIR® series. With a full frame frequency of 1,004 Hz in 640 x 512 format, it captures extremely fast moving objects and highly dynamic thermal processes such as those occurring in explosions, electrical discharges or laser machining processes. Due to the use of an innovative detector with HOT Long-Life technology, the ImageIR® 8300 hs also requires less cooling power and therefore has a significantly longer lifetime.

With the LRM-274, a new miniaturised multi-channel detector has been developed which is ideally suited for integration into measurement instruments for flame sensor technology. For the first time an InfraTec detector contains integrated heating resistors. This allows the user to test the detector himself if required and to check the complete signal chain and components.

The PIR uc 605 is another camera model which completes the portfolio of infrared measurement technology. This radiometric IR camera module, which fits on one hand, is designed for universal use. It is based on an uncooled microbolometer FPA detector with (640 × 480) IR pixels, which provides detailed thermal images in high resolution.

InfraTec infrared LLC, a subsidiary of InfraTec GmbH, founded in the USA in 2007, opens a second branch office. This will expand the local presence to respond appropriately to the success of pyroelectric detectors in the USA, Canada and Mexico.

InfraTec Introduces itself and Further Interesting Facts

2019

InfraTec presents the world's first pyroelectric detector combining eight measurement channels in a TO8 housing with a diameter of 15.2 mm. The LRM-278 operates in current mode and additionally contains a temperature sensor. Measuring the temperature inside the detector, for example, provides the option of compensating the typical temperature drift of the filters very accurately by means of a calibration.

The model variety of the infrared camera series ImageIR® is also growing. The ImageIR® 5300 high-speed model, which has been further developed, allows frame rates up to 105 kHz. Users can thus successfully solve measurement and testing tasks where extremely fast thermal processes have to be captured and recorded.

The special feature of the new ImageIR® 9500, however, is its highly sensitive detector based on mercury cadmium telluride (MCT) with (1,280 × 720) IR pixels. With the help of the opto-mechanical MicroScan, the geometrical resolution of the camera can be increased to 3.7 MegaPixels. This model enables IR frame rates up to 1.5 kHz in sub-frame format with (320 × 180) IR pixels and is sold with extensive accessories worldwide.

For the comfortable analysis of objects with extreme temperature gradients InfraTec developed the new function High Dynamic Range (HDR) for the thermal imaging camera series ImageIR®. The result for the user are high-contrast images in a very wide temperature range of up to 3,000 K, which is characterised by a high measurement accuracy.

2018

At the beginning of the year, the excavators rolled in at InfraTec. The reason for this is the start of a comprehensive expansion of the business premises at the southern location of the TechnologieZentrum Dresden, which were acquired last year. In order to increase the capacity for the production of infrared detectors, 500 m² of additional clean room and social areas are being built. The new building also includes a complete floor of generously designed additional office areas.

Since February InfraTec presents itself with a completely renewed international website. By changing to a responsive web design, the website is now perfectly structured and tailored to the needs of users, even for smaller display sizes of mobile devices.

The high-end camera series ImageIR® comes up with the new ImageIR® 9400. Users of this camera series can choose between two modes - the standard mode with highest geometrical resolution and the high-speed mode. In high-speed mode, the frame rate increases more than three times for the same field of view, while at the same time the thermal resolution improves by a factor of almost 2.

A special model is also added to the VarioCAM® High Definition microbolometer camera series. This is the first uncooled radiometric zoom camera from InfraTec. The thermography system VarioCAM® HD Z has a motorised sixfold infrared zoom lens with a focal length of (25 ... 150) mm for the spectral range of (7.5 ... 14) μm.

With the LRM-244, the series of innovative miniaturized multi channel detectors has now grown to a total of eight models. The main feature of this quad channel detector is its extremely large, symmetrical field of view, which enables the detection of flames in an angular range of more than 90 degrees. The LRM product range thus includes dual and quad channel detectors with and without thermal compensation in housings of various sizes, which are designed for current or voltage operation, depending on the model.

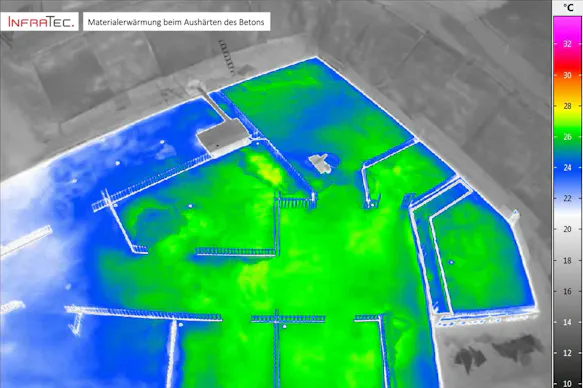

Something is moving on the InfraTec construction site in Dresden! On May 18, 2018, the floor slab for the new clean room extension was poured. We were able to observe this work step for 36 hours with our infrared camera VarioCAM® High Definition. What is otherwise hidden from the human eye can be seen very well with the thermographic camera: The continuous heating of the concrete during the first phase of curing.

2017

The US subsidiary InfraTec infrared LLC celebrates its 10th anniversary. Its foundation as the North American sales office of the Sensor Technology Division was an important milestone towards a predominant, worldwide direct sales of the IR detectors produced in Dresden. Since then, the office has developed into a strategically important factor, handling imports for US customers and ensuring comprehensive application service throughout the entire product life cycle.

Civilian observers of the Organization for Security and Cooperation in Europe (OSCE) use three high-resolution infrared thermal imaging systems of the VarioCAM® HD head security series to monitor compliance with the ceasefire in eastern Ukraine. The cameras are used to solve security and surveillance tasks with high range requirements. Similar systems have already proven themselves on comparable missions in Europe and North Africa.

2016

In keeping with the motto "entirely in the family" and in best summer weather, the InfraTec GmbH Infrarot und Messtechnik celebrated its 25th anniversary.

With the introduction of the ImageIR® 10300, the Infrared Measurement Division is further expanding its leading position as one of the world's leading suppliers of thermography systems. The camera detector with its (1,920 × 1,536) IR pixels offers users from industry and science the at this time highest geometrical resolution for a radiometric calibrated thermal imaging camera with cooled detector and, for the first time, enables images to be taken in Full HD format.

2015

After three years of research and development work, the joint project "Fast Infrared Spectrometer for the Analysis of Hydrocarbons" (SIRKO) ends in February. The result, the XFP-3137, supports InfraTec's technological leadership in integrating tunable micromechanical Fabry-Pérot filters (µFPF).

The Sensor Division is presenting the first miniaturized four-channel detector for gas and flame sensors as a further new development. With its stack design, the LRM-254 embodies a completely new concept that will allow more channels to be integrated in the future without changing the housing size.

The models of the thermal imaging camera series ImageIR® produced at the Dresden site can now be equipped with a 10 GigE interface. Users can better exploit large detector formats in full frame mode because images are transmitted with significantly higher frequencies.

InfraTec continues to expand its presence in the USA. Since summer, InfraTec infrared LLC has also been coordinating the sales of thermography systems.

2014

The infrared sensor technology division was linked to all European customers via a direct distribution channel starting in January. InfraTec presents a new generation of detectors with integrated tunable Fabry-Pérot filter for the first time, with integrated control implemented by an ASIC and an EPROM. The infrared detectors LMM-274 and LIM-272 are presented the first time.

In the infrared measurement department, the first thermal imaging cameras with super zoom lens and HD resolution, ImageIR® 8300 / 9300 Z are placed on the market. The camera series VarioCAM® High Definition is introduced as part of the mobile equipment lines "research" and "inspect" and the stationary version "head". Those cameras are also equipped with other new features such as the "permanent autofocus" and the unique "EverSharp function".

2013

The EU-funded project ESiP, where InfraTec also plays a major role, is awarded the ENIAC Innovation Award. InfraTec is also involved in the EU project "ThermoBot" - development of an autonomous robotic system for thermographic crack detection. The high-speed thermal imager ImageIR® 8300 high performance allows frame rates of 350 Hz for the first time.

2012

Thermographic cameras with detectors of the next generation in Megapixel format VarioCAM® High Definition with (1,024 x 768) IR pixels and ImageIR® 9300 (1,280 x 1,024) IR pixels are launched. The thermography day "Research & Development" with participation of numerous internal and external speakers in the head office Dresden takes place for the first time.

The new product catalog with lots of additional information on the topic of infrared sensors is available.

2011

Together with 260 business partners, customers and personnel InfraTec GmbH celebrated its 20th company anniversary on the 1st of July 2011.

InfraTec participates in the international projects of "Resource-efficient and sustainable production of quality steels with improved on-line process control of the vacuum degassing" and the project of "Turbo Production for Aircraft – automation technology for aircraft".

The Fabry-Pérot detector by InfraTec wins the SENSORS EXPO "Best of Show" Gold Award.

2010

The sensor division receives the Prism Award for Photonics Innovation in the category "Detectors, Sensing, and Imaging Systems" at PHOTONICS WEST for the "MEMS tuneable Fabry-Pérot Interferometer for Infrared Absorption Spectroscopy".

The thermographic software IRBIS® 3 was test winner in a comparison test of various thermographic software products.

InfraTec’s staff exceeds 150.

2009

Introduction of the second generation of high-end camera series ImageIR®, supply of the wordwide first fully automated infrared system for spot weld testing.

2008

Introduction of the newly developed thermographic software family IRBIS® 3, major order for the delivery of 300 VarioVIEW-thermographic systems. Supply of an infrared test system for non-destructive weld seam testing. The sensor division together with Technical University Chemnitz - ZMT and Fraunhofer IZM Chemnitz receives the SENSOR innovation award for 2008 from the AMA professional association for sensor technology. Awarded is the "MEMS tuneable Fabry-Pérot Interferometer for Infrared Absorption Spectroscopy". The subsidiary InfraTec - Infrared Sensor and Measurement Technology Ltd. is founded in Great Britain to care for customers of the sensor division.

2007

New active thermographic system PV-LIT for photovoltaics applications. Foundation of a subsidiary in the USA.

2006

Market launch of the wordwide first mobile microbolometer camera with Mega-Pixel resolution, namely VarioCAM® high resolution.

2005

Foundations of subsidiaries in Great Britain and France.

2004

The size of staff exceeds 80. The Sensor Division introduces two new product series of highly innovative detectors to the market. Within the framework of a long-term contract, InfraTec becomes the worldwide exclusive (except Northern America and Japan) representative of the thermography system manufacturer JENOPTIK Laser, Optik, Systeme GmbH.

2003

An increasing turnover in both divisions requires to additionally hire qualified labour. For improving its presence in the Polish thermography market, InfraTec founds a subsidiary there.

2002

The number of staff exceeds 50. InfraTec supplies automated thermography solutions overseas. Orders received by the Sensor Division from all over the world require substantial extension of the manufacturing capacity.

2001

Staff and their families and numerous domestic and foreign business partners jointly celebrate the company’s 10th anniversary on an Elbe-river steamer.

2000

Sensor engineering production moves into its own additional manufacturing building. Activities regarding multicolour detectors, preferably for gas sensor technology, are bundled under the trademark PYROMID®.

1999

InfraTec offers closed solutions for digital real-time thermography, including security applications. The turnover in pyroelectrical detectors abroad exceeds the domestic turnover for the first time.

1998

The first products of a thermography software family are developed under the trademark IRBIS®. Thermally compensated miniature detectors supplement the product range.

1997

Acceptance of the exclusive representation of JENOPTIK thermography systems in Germany. Laser Components Inc. (USA) and Laser Components Ltd. (GB) start actively selling InfraTec detectors.

1996

Supply of the first automated thermographic system for early fire detection. The Sensor Division has a complete range of pyroelectrical detectors for modern system concepts as well as a replacement for standard products.

1995

Participation of the Infrared Measurement Division in the INTERKAMA, a major international measuring technology fair, in order to start worldwide sales of the company’s own thermography-automation solutions.

1994

The Infrared Measurement Division expands its scope of products and becomes active all over Germany.

1993

Relocation to larger business premises at the new location of TechnologieZentrumDresden, Gostritzer Straße. Setup of a small complete manufacturing line for pyroelectrical detectors.

1992

Participation in the model test of "Technology-oriented Business Foundation in the New Federal Sates" as good support in developing an efficient technology for the microelectronic manufacture of infrared detectors. Laser Components GmbH, a company in Munich, starts selling InfraTec detectors.

1991

After its foundation in February, the company InfraTec GmbH Infrarotsensorik und Messtechnik is entered into the Dresden Trade Register on 24th of June. Start of business activities, preliminarily on premises rented from the Dresden University of Technology and immediatly after that at the location of TechnologieZentrumDresden in Bergstraße. Compact multicolour detectors of 2 to 4 spectral channels for gas analysis to enter the sensor market available for supply.

1990

Foundation of the engineering office InfraTech GbR (partnership) by Dr.-Ing. Heinze and Dr.-Ing. Krauß; preparations for founding a GmbH (limited liability company); the first supplier contract for pyroelectrical detectors is concluded.