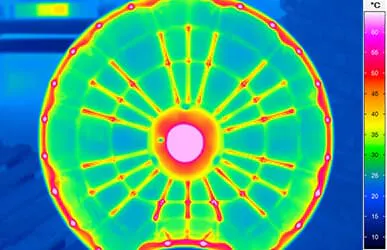

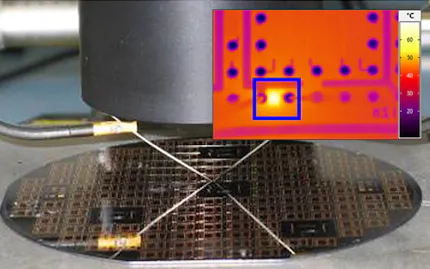

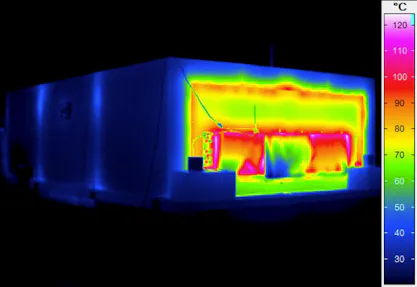

Application possibilities of thermography

Which Applications is Thermography Qualified for as a Method of Measurement and Testing?

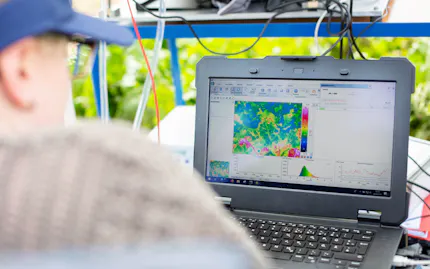

The field of play for thermography is very large and provides outstanding possibilities for a considerable number of industries and applications. We are also learning something new every day are constantly discovering new fields of application which we do not want to deprive you of. Or would you know ad hoc what an infrared camera has to do with the agricultural sector?