Do Not Let Anything Burn

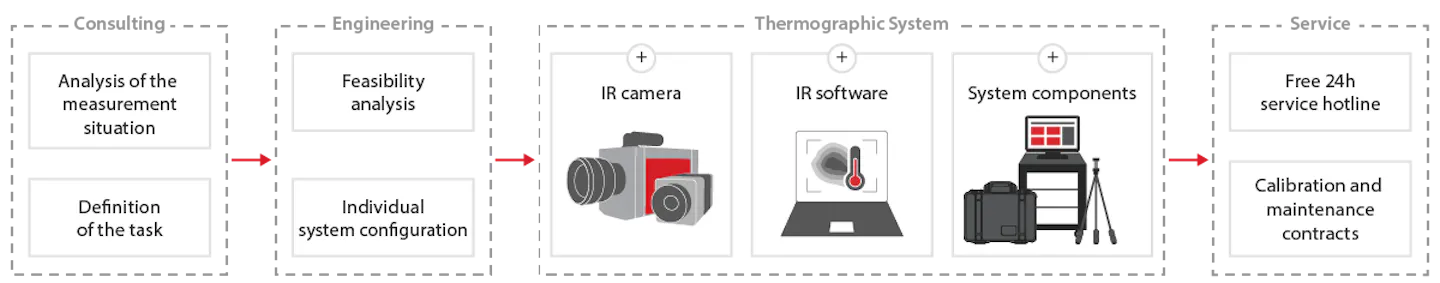

In addition to individual thermography cameras, our product portfolio also includes bespoke turnkey thermographic automation solutions. Based on a proven and tested building block system we are providing individually configured system solutions which are customised precisely to your requirements. One of these system solutions for object and warehouse monitoring is FIRE-SCAN.

Customised and Turnkey System Solutions by InfraTec

Monitoring the Situation Closely with FIRE-SCAN

In the context of climate neutrality e-mobility and the storage of electric energy from renewable sources are important issues for today‘s and tomorrow‘s society.

High-capacity accumulators for electric energy, like the lithium-ion batteries prevalent today, occupy the crucial key position here. In addition to their significant role and numerous undeniable advantages the manufacture, transport, storage and also usage of lithium-ion batteries harbour many risks. Because these energy stores can sometimes react extremely sensitively to influences like temperature fluctuations, damage or vibrations the requirements for providing safety measures are very high, especially when this involves spatially concentrated larger quantities.

The thermography automation solution FIRE-SCAN for lithium-ion batteries is a reliable complement to other safety precautions. In continuous operation 24/7 it enables the automatic monitoring of temperature development at work places, storage areas or complete BESS (Battery Energy Storage Systems) and should therefore be an essential part of your risk management. The system consists of one or several high-performance infrared cameras and the associated software, reliably localises heat sources and measures their temperature gradation over time. If pre-established temperature threshold values are exceeded, FIRE-SCAN automatically triggers an alarm and thus enables the rapid launch of appropriate fire prevention measures.

Our System Solutions

What Does a System Solution Involve?

The core of every system solution is an InfraTec infrared camera with detector formats of up to (2,560× 2,048) IR pixels. In addition to the thermography camera the complete solution includes transmission and indicator units as well as industrial PC and software components. If the environmental conditions require it, ATEX certified protective housing and pan/tilt heads can also be used.