InfraTec participation in EU Project “ThermoBot“

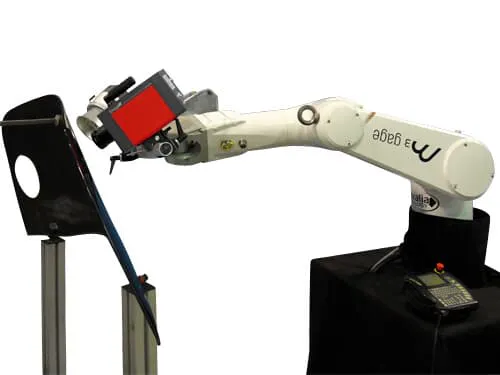

Non-destructive testing of components is an important auxiliary process step, not only in post-production but also in regular maintenance. In the project “ThermoBot“ a fully automated test system is being developed in corporation with InfraTec. This system shall replace previous techniques in crack detection, such as the ecologically undesirable and poorly automatable magnetic particle inspection. The test sequence for each new component is based on its 3D-CAD construction data. The robot uses a process model of thermal image as well as a work-cell simulation to plan a collision free robot path with complete coverage of the area to be tested. During the inspection the system performs the thermographic test including image segmentation, fault detection and classification. Simultaneously, an online process simulation takes place to evaluate the quality (contrast) of the images. Real-time results are transferred to the robot control to adapt the robot path in case of any unknown deviations (geometry, surface structure, thermodynamic properties). Applications for the system are intended in testing metal components as well as components made from compound materials in the automotive and aircraft industry, during production as well as regular maintenance.

The research leading to these results has received funding from the European Union Seventh Framework Programme (FP7/2007-2013) under grant agreement No. 284607.