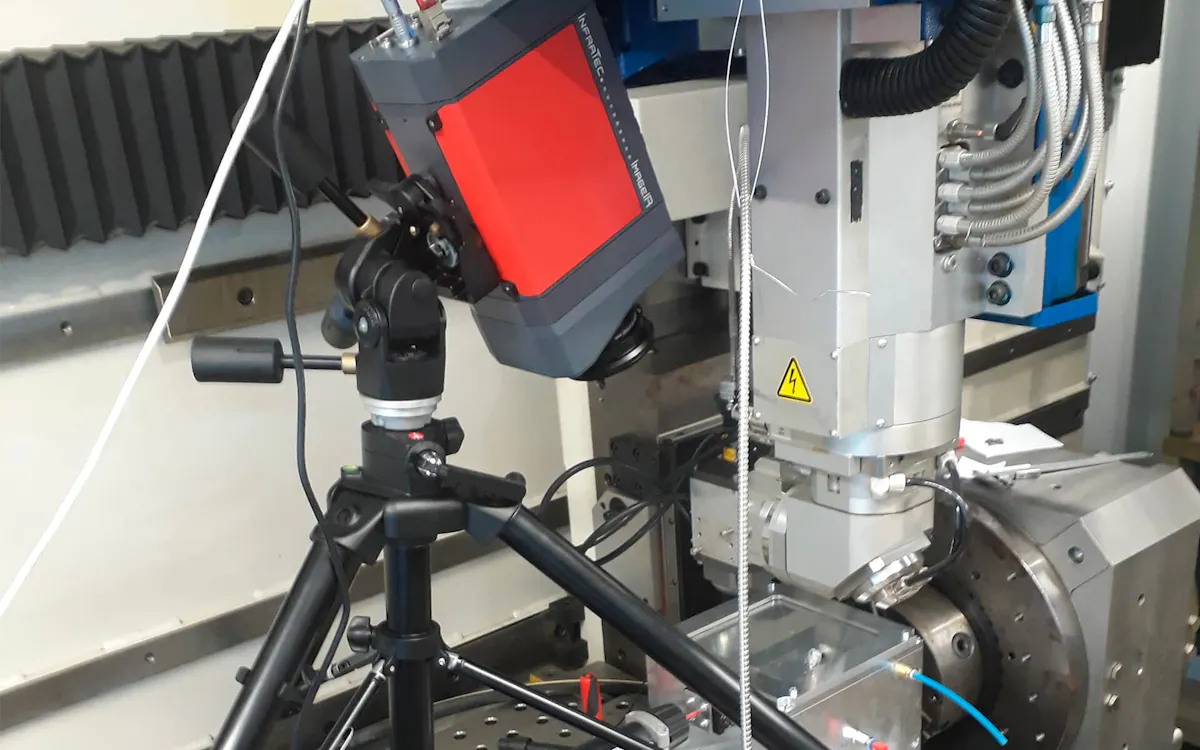

Case Study: Use of High-speed Thermography in Laser High-temperature Capillary Gap Brazing

Due to their flexibility, they serve as a key technology for implementing the goals of industry 4.0. Although laser cutting and welding are nowadays regarded as turnkey technologies, the majority of laser applications, for example joining of hybrid materials, 3D printing or ultra-short pulse processing, still require considerable research and development.

The LaserApplicationCenter (LAC) of Aalen University intensively researches and develops new methods of laser material processing. Thus, innovative materials for Additive Manufacturing are developed and investigated within public R&D projects, including magnetic materials or electrical energy storage materials for electromobility. Another focus is lightweight construction. Here, among other things, mixed metallic compounds and hybrid lightweight structures made of aluminium and CFRP for CO2-efficient mobility concepts are investigated. The newly developed processes aluminium laser polishing and high-temperature capillary gap brazing are already being used in industrial projects.

Making Heat Flow Visible

Laser processes are highly dynamic thermally induced processes that cannot be detected with the naked eye. High-speed visual cameras that are often used are not capable of visualising the heat flow in the component. A contacting temperature measurement of the moving very small liquid metal is not possible. In addition, the processing zone should remain free of influences from the measurement system. This is exactly what thermographic cameras do, which provide high frame rates with high spatial resolutions at the same time.

Get further information about thermography in laser high-temperature capillary gap brazing