Online Event: Applications for Thermal Imaging on Wind Power Systems

Around the world more and more electricity is generated from wind power. As the number of wind turbines increases, so does the need to monitor them and optimize their efficiency. Contamination or erosion of rotor blades or damage to auxiliary equipment such as boundary layer fences, vortex generators and zigzag belt turbulators can significantly reduce the yield. Thermography offers an efficient way to detect these defects from a distance of several hundred meters and while the rotors are running.

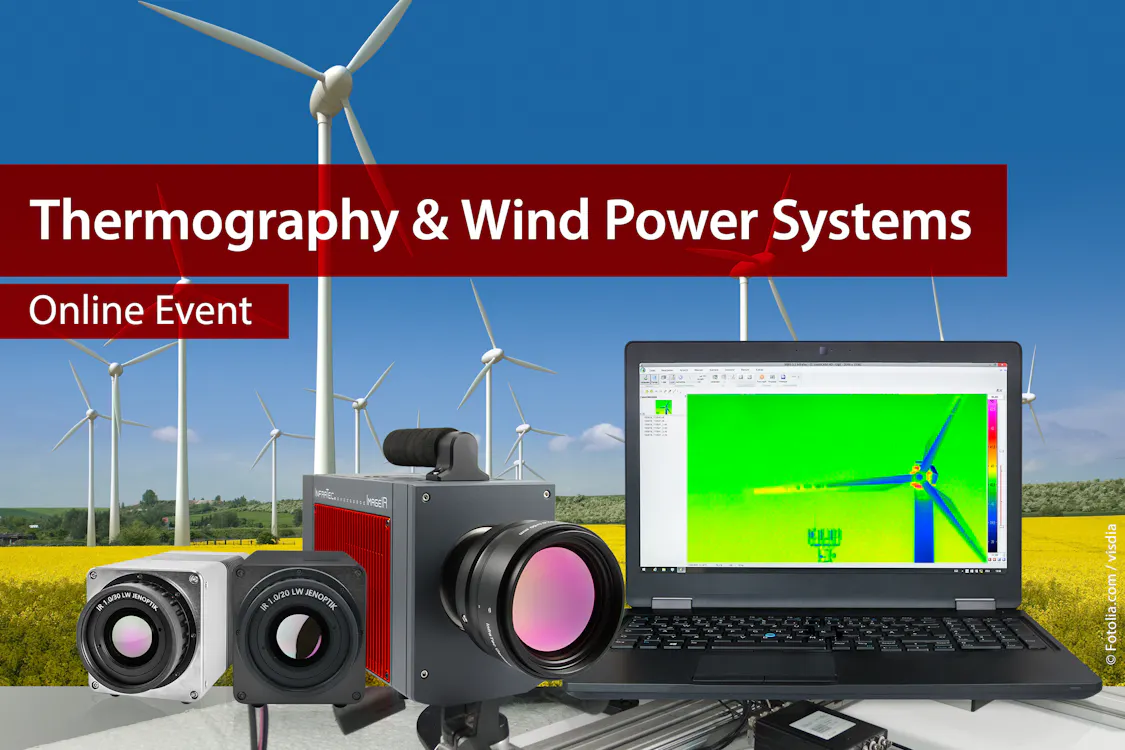

In the online event “Applications for Thermal Imaging on Wind Power Systems”, the InfraTec experts explain how thermography can be used for the optimization, development and maintenance of wind turbines.

In addition to general information on infrared thermography, participants will learn more about the various infrared cameras and the tasks for which they are suitable. One focus will be on non-destructive material testing using active thermography.

Online Event: „Applications for Thermal Imaging on Wind Power Systems”

Including the technical lectures from thermography practice:

„Inspection of Wind Turbine Blades with Ground-based Passive Thermography”

Speaker: Michael Stamm, BAM Federal Institute for Materials Research and Testing

Date: Wednesday, 19 March 2025

Time: 10:00 AM – 12:00 PM (CET)

Registration