![InfraTec - WASTE-SCAN ARC Copenhagen InfraTec - WASTE-SCAN ARC Copenhagen - © ARC amager ressource center]() 2021-10-27Case Study: Early Fire Detection in Incineration PlantInfrared Thermography Increases Safety in Waste to Energy PlantRead onDownload PDF-File (608 kB)

2021-10-27Case Study: Early Fire Detection in Incineration PlantInfrared Thermography Increases Safety in Waste to Energy PlantRead onDownload PDF-File (608 kB)The Amager Resource Center (ARC) is a waste incinerator like no other. From the roof of the Waste to Energy facility, skiers and snowboarders wind their way down on green plastic mats from a height of about 80 meters, even in the summer. The city hall of the Danish capital, Copenhagen, is just five kilometres away. The location, which is almost in the heart of a European capital, as well as its use as a public leisure centre, shows how much confidence operators place in the safety of the ARC. An important component in the security concept is the WASTE-SCAN infrared monitoring system for early fire detection by InfraTec.

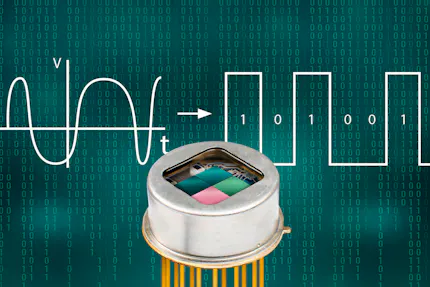

![Digital pyroelectric detector from InfraTec Digital pyroelectric detector from InfraTec - Picure credits: © istockphoto / gsshot]() 2021-10-12Go Digital – Reaching the Goal More Quickly with Less EffortThe pyroelectric detector becomes digital and supplements the portfolio of analog detectors.Read onDownload ZIP-File (3759 kB)

2021-10-12Go Digital – Reaching the Goal More Quickly with Less EffortThe pyroelectric detector becomes digital and supplements the portfolio of analog detectors.Read onDownload ZIP-File (3759 kB)InfraTec has been developing and producing pyroelectric detectors for over 30 years now. They have been tried and proven for numerous demanding customer applications in recent decades. However, to reduce the expenditure for customers and to facilitate the system integration of a detector, InfraTec has developed the digital pyroelectric detector (LRD).

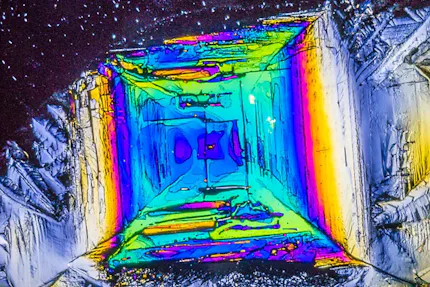

![Polarisation microscopic image of crystallised Rochelle salt Polarisation microscopic image of crystallised Rochelle salt]() 2021-08-13Life with PyroelectricityFerroelectricity: 100 years and very much alive and kicking. This phenomenon has been researched and used until the present day.Read onDownload ZIP-File (3068 kB)

2021-08-13Life with PyroelectricityFerroelectricity: 100 years and very much alive and kicking. This phenomenon has been researched and used until the present day.Read onDownload ZIP-File (3068 kB)Science lives from ambitious and inquisitive people. Progress would be inconceivable without them. In the field of infrared technologies, the researchers and developers of InfraTec make a decisive contribution to the advanced development of pyroelectric detectors with their visionary ideas and expertise.

![Data Fusion in Plant Phenotyping for Cercospora Detection in Sugarbeets Data Fusion in Plant Phenotyping for Cercospora Detection in Sugarbeets]() 2021-07-16A Successful Cooperation against Plant DiseasesData Fusion in Plant Phenotyping for Cercospora Detection in SugarbeetsRead onDownload ZIP-File (944 kB)

2021-07-16A Successful Cooperation against Plant DiseasesData Fusion in Plant Phenotyping for Cercospora Detection in SugarbeetsRead onDownload ZIP-File (944 kB)Various sensor technologies had been evaluated regarding their usability for the detection of the plant disease Cercospora in the joint project „Data Fusion in Plant Phenotyping for Cercospora Detection in Sugarbeets“ (DataPlant), funded by the German Ministry of Food and Agriculture.

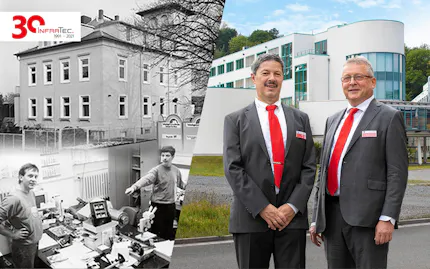

![InfraTec - 30 years company anniversary InfraTec - 30 years company anniversary]() 2021-06-2430 Years Under the Spell of InfraredHow an efficient, medium-sized Dresden high-tech company developed from one idea.Read onDownload ZIP-File (3448 kB)

2021-06-2430 Years Under the Spell of InfraredHow an efficient, medium-sized Dresden high-tech company developed from one idea.Read onDownload ZIP-File (3448 kB)Infrared technology has exclusive and sometimes mysterious properties because it uses electromagnetic radiation, an invisible, but at the same time, omnipresent force. It can be used, for example, to measure temperatures and gas concentrations, for early fire detection and to track down energy losses.