Gas Analysis

A pyroelectric detector has a big potential when used in gas analysis devices. The gas identification and inequality measurements are based on a non-dispersive (without spectral fragmentation) absorption spectroscopy of infrared light (NDIR), for which interference filters with (3 ... 5) µm or (8 ... 12) µm are used to select gas specific bandwidths (100 … 200) nm.

Pyroelectric Detectors in Gas Analysis

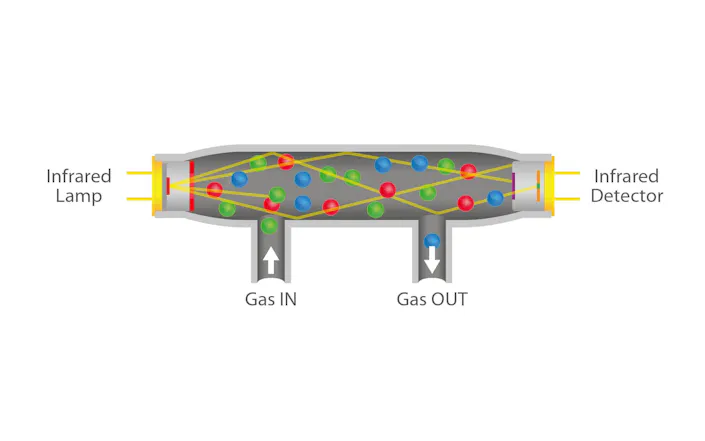

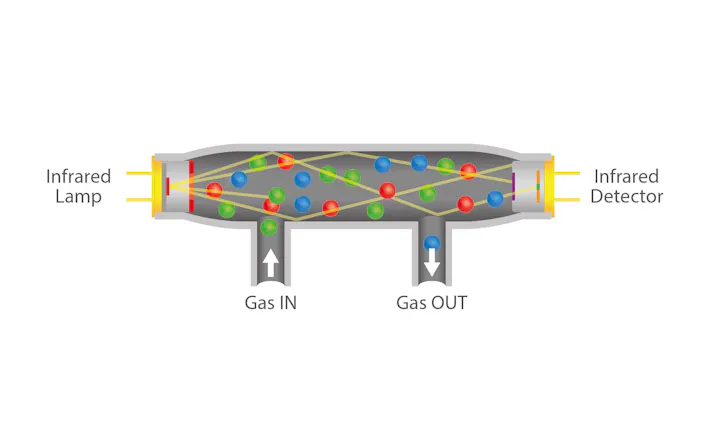

A large number of gases absorb infrared radiation by intramolecular vibrations. For each specific material, the absorption intensity depends on the wavelength of the infrared radiation. This principle uses a non-dispersive infrared gas analyzer (NDIR gas analyzer) for gas analysis. The analyzer consists of an electronically or mechanically modulated infrared source, a sample cell through which the gas flows to be measured, and a pyroelectric detector.

In the detector cap, a narrow band pass filter (NBP Filter) is integrated, whose pass band corresponds to the absorption wavelength of the target gas. With the thermal detector, the transmission of the measured gas mixture is determined in a defined arrangement. If the gas being searched for is not present, most of the infrared radiation will reach the detector and the signal will be at its maximum. If the concentration of the gas increases, absorption will also increase according to Lambert-Beer's law, and the signal will reduce accordingly.

This concept finds itself again in standard InfraTec infrared filters with a center wavelength (CWL) of 4.27 µm and a half power bandwidth (HPBW) of 170 nm are suitable for the measurement of carbon dioxide (CO

Infrared Sensor for Gas Analysis

As opposed to dispersive grating- or FTIR-spectrometers, NDIR gas analysis cannot resolve complex forms of absorption bandwidths. Instead it uses an averaged signal measurement within the filter pass band. With this, you now have a manageable, long-time stable and continuously operating measurement method for industrial gas analysis at your disposal. Gas identification and transverse sensitivity of gas mixtures often require spectral multi-channel evaluations.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.

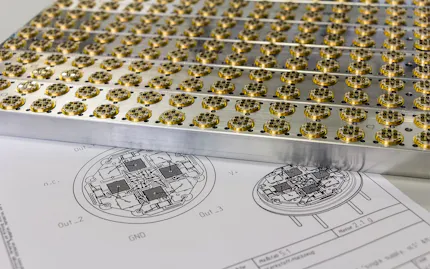

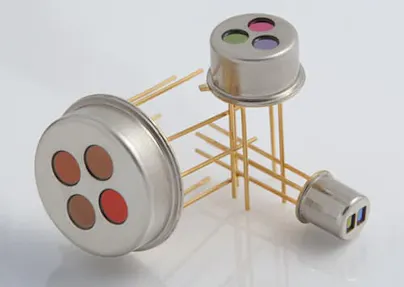

InfraTec Offers a Variety of Single- and Multi-Channel Detectors for Gas Analysis

The classic gas analysis setup with filter wheel and/or mechanical chopper requires relatively fast (> 200 Hz) pyroelectric detectors with strong output signals. For this purpose, we offer multiple types with integrated JFET or CMOS operational amplifiers and pyroelectric elements, which are wired up for current mode operation.

A Multi-channel (gas and reference channels) detector for gas analysis is often lighted by electrically modulatable radiators. Thus, this is required to have high stability and signal-noise-ratios even at low frequencies. InfraTec also offers components, so called beam splitters, with patented constructions, which split the light of a single entrance window geometrically into two or four channels. This allows for a very precise gas analysis.

Technical Article: Use of Multi Channel Detectors and Infrared Emitters in Gas Analysis

The detection and concentration measurement of gases is a standard procedure in the medical and industrial area worldwide. But what needs to be observed for the selection of components and what do multi channel detectors and infrared emitters have to do with this?

Pyroelectric Detectors for Gas Analysis

Properties of single channel detectors

One measuring channel

High power

Temperature compensation

Reduced acceleration response

Single or split power supply

Properties of multi channel detectors

One measurement and one reference channel

Temperature compensation

Single or split

Power supply