Thermography for Flow Analysis

Flow processes are omnipresent and they play an important role in technology, nature, in climate and weather, and also in medicine. Fluid mechanics is a fundamental prerequisite for life on earth. Thermal imaging is one method of observing and analysing flows. This method visualises characteristic thermal signatures which are caused by different heat transfer coefficients.

This allows to determine both the direction and strength, but above all the type of flow – turbulent or laminar.

Fluid Mechanics

With the aid of thermal imaging, the flow properties of various fluids and solids can be made visible and analysable. Thermography as a non-contact, area-based and imaging temperature measurement method is perfectly suited to detect even the smallest flow-induced temperature gradients of less than 15 mK without influencing the flow behaviour itself.

By the use of thermography systems, diverse fluid mechanics can be recorded and analysed:

Flow of fluids in the form of gases,

for example turbulence research, aerodynamics, detection of process gases

Flow of fluids in the form of liquids,

for example fresh and waste water, oil or chemicals, riversEnvironmentally relevant flows within the scope of geologic and climatic research,

for example fluid mechanics of lava flows, rock and snow avalanches

Flow in thermotechnical plants and systems,

for example detection of decreases in pressure, flow streams and heat transfers

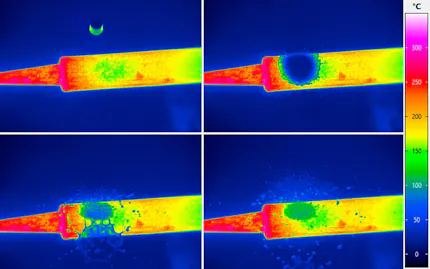

Aircraft Aerofoils in the Wind Tunnel: Aerodynamics Research

To sustainably improve the efficiency and performance of aeroplanes, numerous research projects are addressing the continuous improvement of aerodynamics. Here, in addition to the fuselage, the wings play a decisive role. The aerofoils are tested in the wind tunnel under various scenarios with the goal of optimising their configuration so as to reduce fuel consumption and also the effects of turbulences.

Since thermal imaging is a non-contact measurement and test method, the air stream behaviour in the wind tunnel can be visualised with the aid of thermography systems without affecting the flow processes. The measurement is based on the temperature difference between the object under test and the flow medium. Sections with different flow conditions caused by surface frictions and an associated heat transfer can be differentiated thermographically as a result.

In addition, with the aid of infrared cameras, it is possible to extensively record and analyse data via software in real time. The software moreover provides the benefit to be able to compensate for vibrations occurring in the wind tunnel and thus to deliver meaningful visual data. It is also possible to operate the camera over large distances.

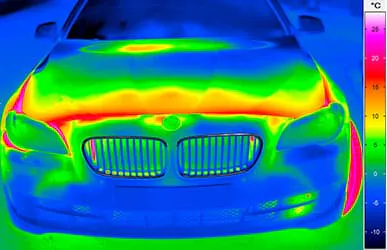

Aircraft and Motor Vehicles in the Wind Tunnel: Aerodynamic Simulations

The automotive and aerospace industries have recourse to the benefits of wind tunnels too. The path to more powerful and economical vehicles proceeds by way of aerodynamic optimisation. This can be achieved by the shape and the design of the vehicle, but also by the weight distribution.

During the test in the wind tunnel, infrared cameras identify both laminar and turbulent flows and enable conclusions on the aerodynamics of the car or plane to be reached. With these insights, motor vehicles or aeroplanes can be optimised in their design in such a way that the air flow is channelled to the appropriate sections and the vortex build-up is controlled so that the aerodynamic drag is reduced.

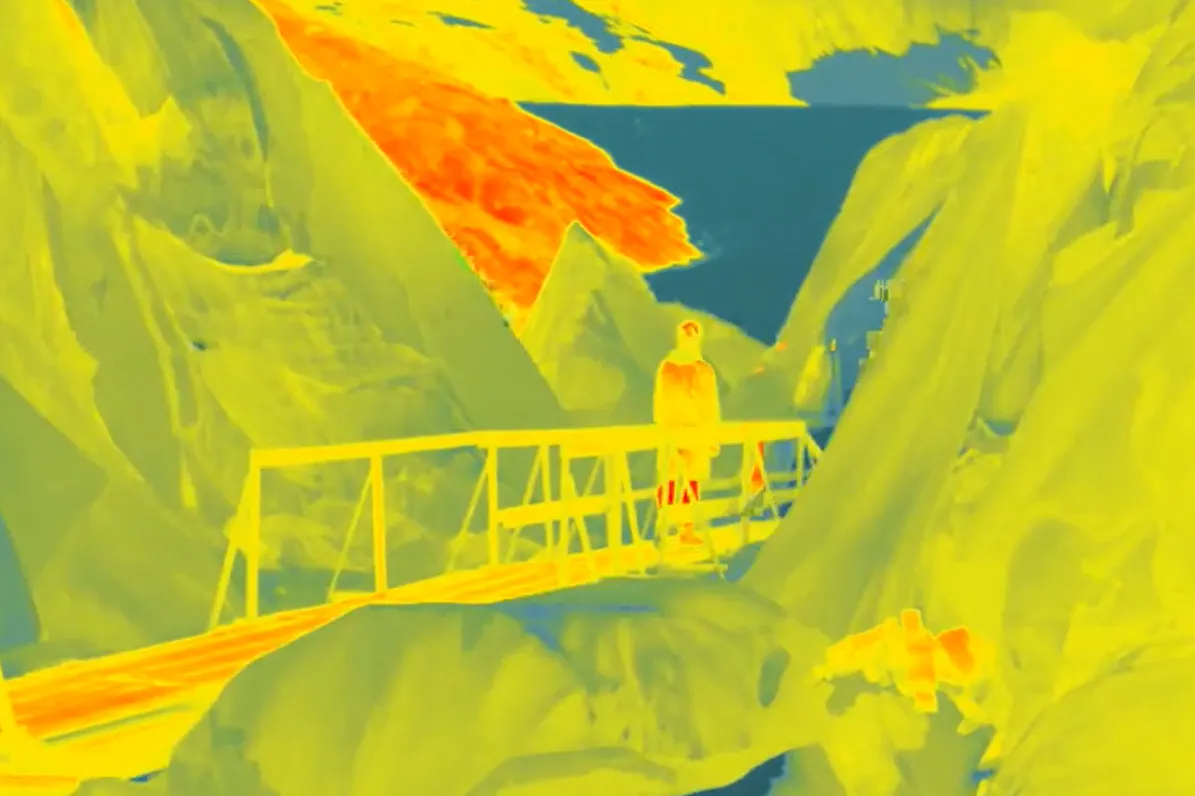

Thermography at Work for Geological and Climate Research

Within the scope of environmental and geological studies, thermography facilitates, among other things, the extensive analysis of natural or urban microclimates and enables conclusions on local conditions to be reached as a result. Here, in addition to liquid flows, air and solid flows are examined as well.

That way, with the aid of thermography, behavioural patterns of snow avalanches, for example, can be analysed. This contributes to better understanding the dynamic avalanche movements and adopting precautionary measures, for example the targeted erection of avalanche barriers and netting. The same applies to rock avalanches. The thermographic recording of rock avalanches in real time allows researchers to study their behaviour under varied conditions and temperatures. Long-term thermography monitoring can contribute to tracking changes in the activity of rock avalanches in the course of time and to identifying trends.

Within the scope of work on and in rivers (bridges, river locks, fish ladders, etc.), thermography data can provide significant information about flow patterns by the infrared camera and software making vortices or flow ranges visible. This is done by recording differences in temperature degree and emissivity between various layers and flows.

Temperature change of a Glacier

Thermography for Monitoring Thermotechnical Plants and Systems

The use of thermography systems for monitoring thermotechnical plants and systems assists in the early detection of irregularities before they cause failures or safety hazards.

Thermal imaging thus allows the analysis of heat transfer in a liquid, relevant, for instance, in the cooling of electronic components, the analysis of heat exchangers or the optimisation of heating systems. Potential decreases in pressure, flow streams and heat transfers in complex fluidic and thermal systems can be identified early as a result. Disruptive geometric influences on the heat exchange dependent on flow can then be rectified, for example in cooling systems based on convection.

Reliably Identifying Disruptive Factors of Wind Energy Turbines

The efficiency of a wind energy converter affects the energy yield (AEP – Annual Energy Production) and with it the profit of the operator. Based on decades of aerodynamic research, the rotor blades of modern wind energy turbines are already significantly optimised. The goal is to get a rate of laminar flow as great and as controlled as possible to the interfaces between the rotor blade and the wind streaming in because turbulent flow decreases the efficiency. This flow develops, for example, due to the soiling or erosion of the rotor blades, but also because of damage to aerodynamic ancillaries (wing fences, vortex generators, etc.).

Thermography is a reliable method for identifying aerodynamic disruptive factors without taking the wind energy turbine out of service and applying invasive auxiliary means. It provides the possibility of detecting defects from several hundred metres distance to the rotors of wind energy converters in operation in order to be able to initiate effective steps to correct them subsequently.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Applications for Thermal Imaging on Wind Power Systems

General information about infrared thermography and presentation of different infrared camera techniques

Monitoring wind turbine power plants by (passive) thermography

Principle & methods of active thermography and examples

Flow Analysis Using Thermal Imaging

General information about infrared thermography

Presentation of different infrared camera techniques

Presentation of different flow types and how to measure them with thermography

Demonstration of different application possibilities, e.g.: aerodynamic optimisation, heat management industry, environmental research, geological research