Inspections of Mechanical Components

Mechanics = movement = heat

Thermal imaging makes it visible

Thermography can indicate mechanical stress caused by pressure, draft and friction

Inspections from safe distance possible

Fast infrared camera systems can resolve movements and indicate faults precisely in time

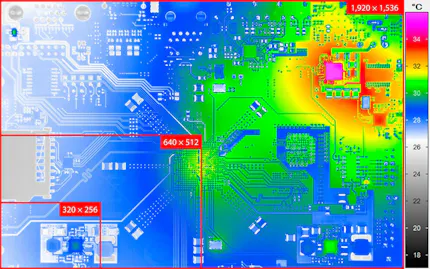

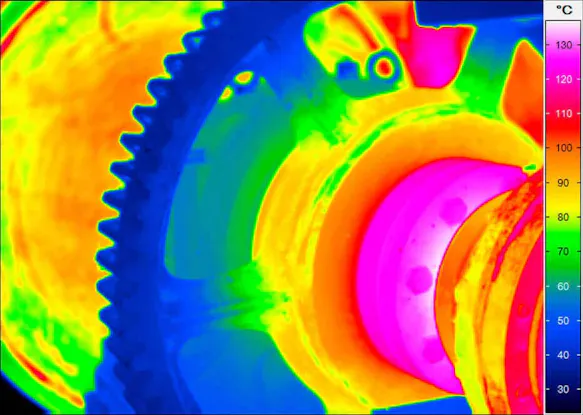

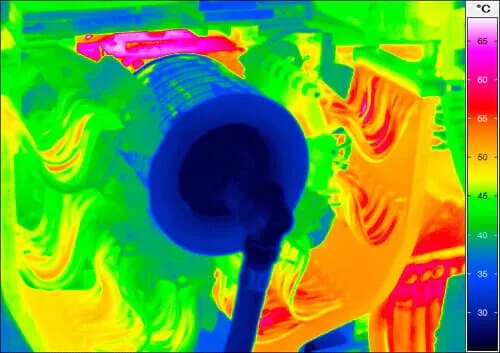

Acquisition of Temperature Changes Caused by Draft, Pressure or Friction During Operation

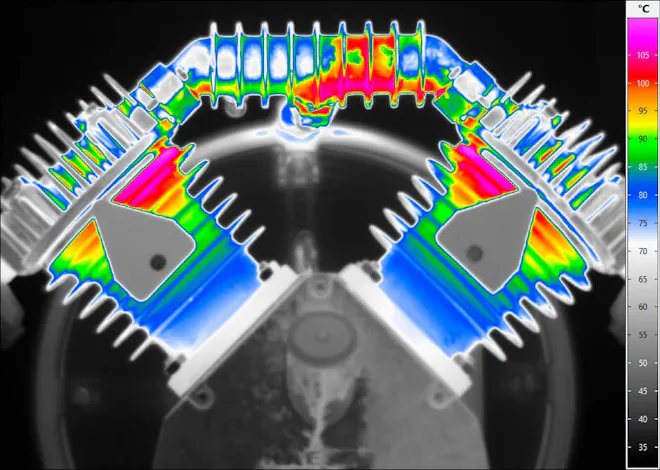

Mechanical components get loaded by pressure, draft or friction during operations. Those load types will all result in an increased temperature. Like this the running of a spindle will result in friction even though being well lubricated. If the spindle is not well positioned the friction will even increase. Infrared camera systems provide a fast overview of the status of the operation long before indications can be seen without such a device.

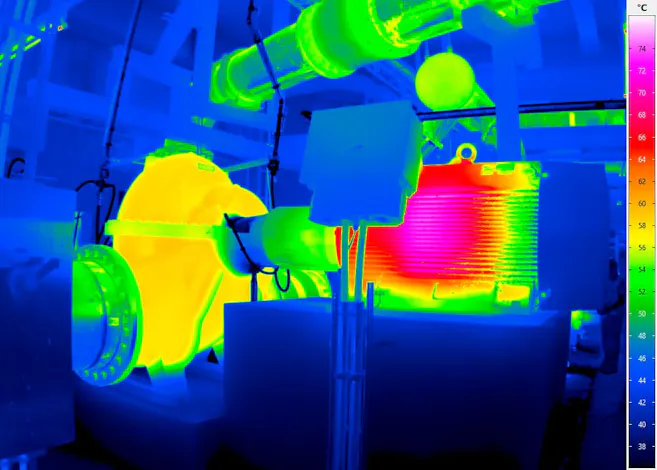

Thermography Allows Inspections from a Safe Distance

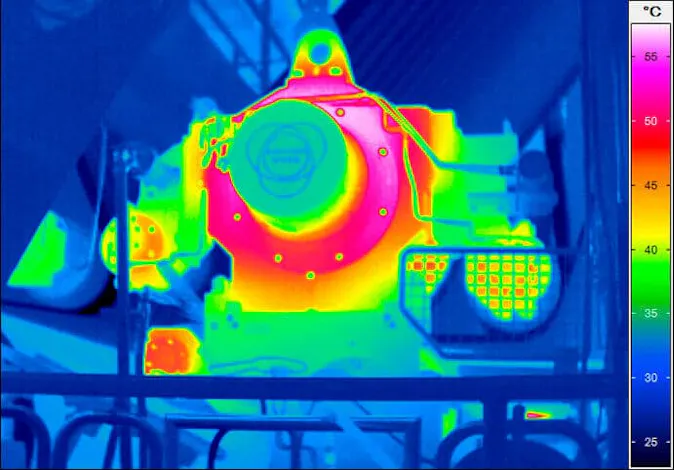

The non-contacting nature of the thermographic measurements is a big advantage. Maintenance personnel can inspect rotating or other fast moving machine parts from outside a dangerous zone. Inspections are additionally eased up as a visualisation of the inspected area is provided.

Thereby, in case of emergency, first actions can be taken even before any profound analysis of the data has been carried out. Preset temperature thresholds for alarming and other personalized settings also help to get maintenance teams productive in very short time.

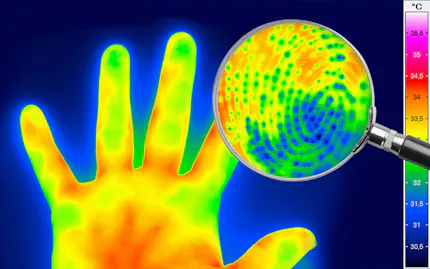

Fast Movements Can Be Resolved by Infrared Camera Systems with High Frame Rates

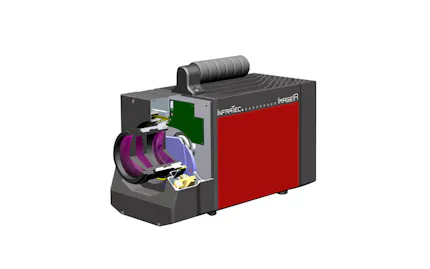

Many mechanical movements run at high speeds. Infrared camera systems should be able to resolve such movements to selectively detect faults. Frame rates of up to 60 Hz in full frame mode of the inspection cameras out of the VarioCAM® High Definition series provide with exactly this advantage. Combined with sequence analysis tools of the thermographic software IRBIS® 3 smallest faults can be found right in the moment of emergence and subsequently those faults can be eliminated.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.