VarioCAM® HD head 900

With its 3.1 megapixels in IR-format the worldwide unique infrared system VarioCAM® HD head 900 gives a new definition to the premium segment of uncooled industrial cameras and guarantees for precise infrared recordings in brilliant photographic quality.

Image format: (2,048 × 1,536) IR pixel opto-mechanical MicroScan feature

Recording and storage of IR frames rates with up to 240 Hz

GigE- and process interface

Rugged light metal housing IP67*

Integrated into camera, genuine temperature measured values

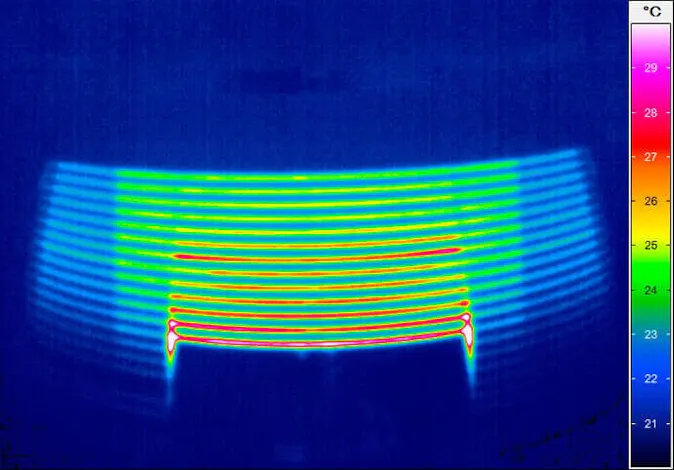

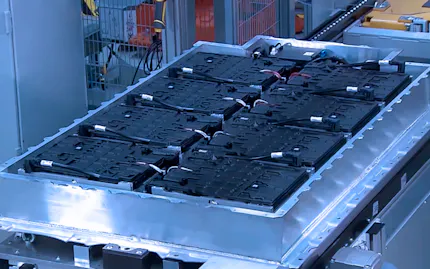

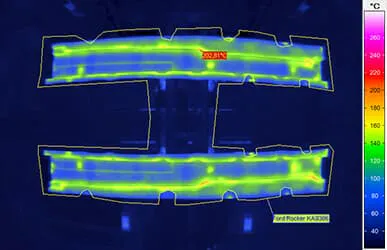

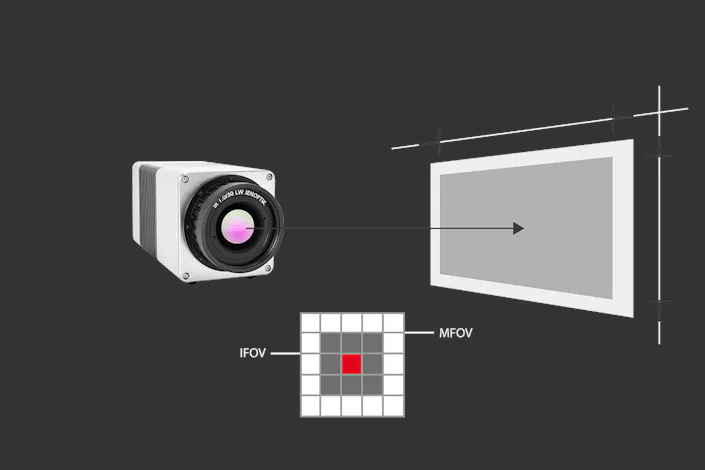

Efficient measurement of smallest structures on large-scale objects

Precise detection of smallest temperature differences

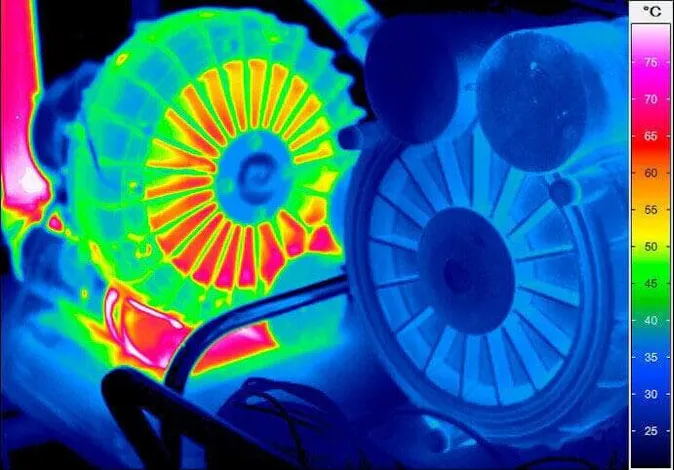

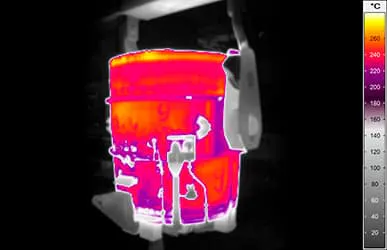

Analysis of high-speed dynamic temperature changes and processes

Easy and inexpensive installation in harsh process environments

Geometric Resolution of 3.1 Megapixels Due to an Integrated MicroScan Feature

The MicroScan technology works opto-mechanical and is designed for permanent operation. Due to FPA detectors of the latest generation with (1,024 × 768) IR pixels, this technology allows for a quadruplication of IR measurement pixels. They show real temperature values but not interpolated pixels. This opens up several new fields of application. Old measurement tasks become more efficient and therefore, valuable working time and costs are saved. Large-scale or far-flung measurement objects can now be recorded in one, fast, precise and complete recording due to the unique MicroScan technology.

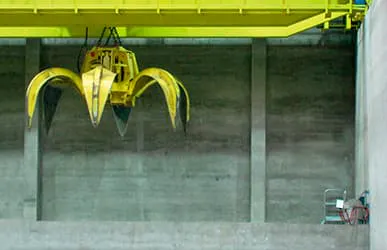

Unrestricted Operation of the Infrared Camera in Harsh Industrial Environments

The robust light metal housing (protection degree IP67*) provides reliable protection for the high sensitive optronics of the device. In addition, it guarantees trouble-free operation even in harsh industrial environments and keeps constant the excellent optical and metrological performance parameters of the device over a long service life. In this way a long-term and trouble-free operation of the VarioCAM® HD head is guaranteed. The usage of a high-quality LEMO connector technology ensures a high protection degree of the infrared camera even for computer-based network operations. For applications in extreme ambient conditions there are suitable protective housings available, for example made of stainless steel. These are optionally equipped with a cooling, heating or both.

Permanent Autofocus for Optimal Focusing

Constantly changing object scenes require manual or automatic refocusing activated by the user. The integrated permanent autofocus function facilitates this work. In case there is a scene change the camera automatically adopts fast and precise the optimal focusing.

Storage of Fast Infrared Sequences with up to 240 Hz

In case of sudden temperature changes, the infrared camera VarioCAM® High Definition provides a sub-frame modus (“subwindowing”) that is usually only found in cooled infrared cameras. The VarioCAM® HD series allows recording of infrared sequences with frame rates up to 240 Hz. In order to reach such high frame rates, each time a defined section of the detector is being read.

The following frame rates are available:

Full-frame with(1,024 × 768) IR pixels: 30 Hz

Sub-frame with (640 × 480) IR pixels: 60 Hz

Sub-frame with (320� × 240) IR pixels: 120 Hz

Sub-frame with (1,024 × 96) IR pixels: 240 Hz

Infrared Camera VarioCAM® High Definition of InfraTec

High-precision Calibration of Infrared Cameras Enables for High Accuracy of Measurements

The infrared camera VarioCAM® High Definition is calibrated using special algorithms. The specially developed calibration algorithm, with more than just a few calibration curves, is used for compensation of temperature fluctuations. Therefore, highest measuring accuracy and repeatability even at changing environmental temperatures is ensured. The exceptional high measuring accuracy can be reached across a wide temperature range.

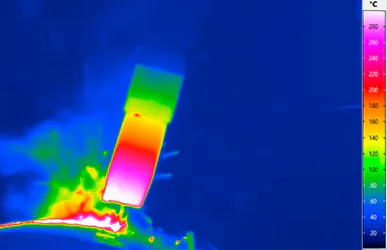

Detection of Minor Defects through High Thermal Resolution

The thermal resolution describes the process to dissolve slightest temperature differences and thus, can display this measurement value. The infrared cameras of the VarioCAM® HD series have a high thermal resolution of up to 0.02 K that helps to display even slightest temperature differences with accuracy. In combination with the high-performance lenses this helps to detect critical faults at an early stage and display these in excellent quality.

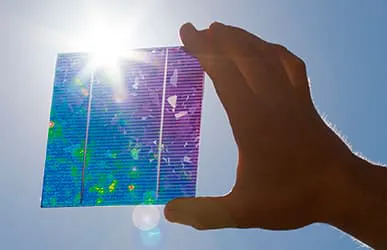

Comprehensive Range of Precision Interchangeable Lenses Enables for a Wide Range of Applications

Due to the comprehensive range of lenses for infrared cameras, a wide range of measurement objects is available, starting with micro thermography to telephoto lens applications for objects in a large distance. The optics of the VarioCAM® HD series were designed as uncompromising full lenses with an opening number of 1.0, highest transmission and transmission quality as well as low distortion.

Automatic Functions of the Infrared Camera

The numerous automatic functions, such as autofocus, automatic image optimisation, automatic hotspot display, automatic calibration range switch etc. enable a fast and effective operation.

Technical Specifications

| Spectral range | (7.5 … 14) µm |

| Detector | Uncooled Microbolometer Focal Plane Array |

| Detector format (IR pixels) | (1,024 × 768) |

| Image format with opto-mechanical MicroScan (IR pixels) | (2,048 × 1,536) |

| Temperature measuring range | (-40 … 2,000) °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | Up to 0.02 K* |

| Frame rate | Full-frame: 30 Hz (1,024 × 768), sub-frame formats*: 60 Hz (640 × 480) / 120 Hz (384 × 288) / 240 Hz (1,024 × 96) |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

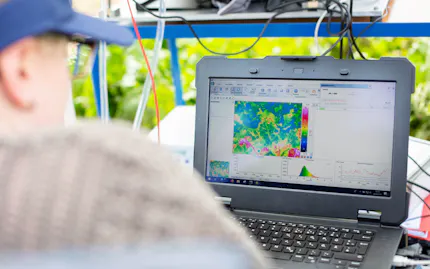

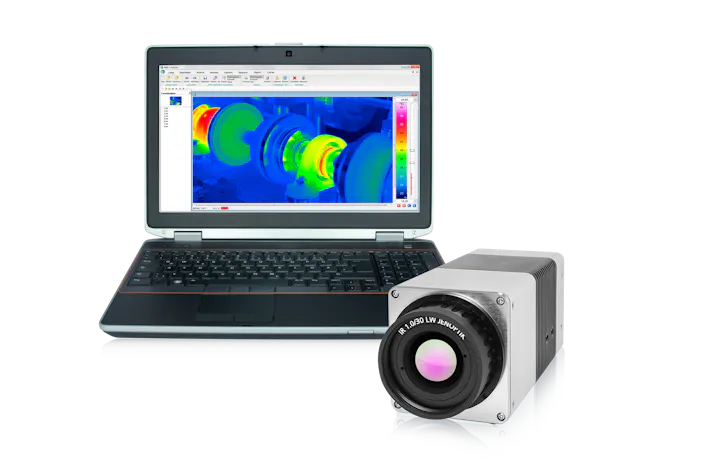

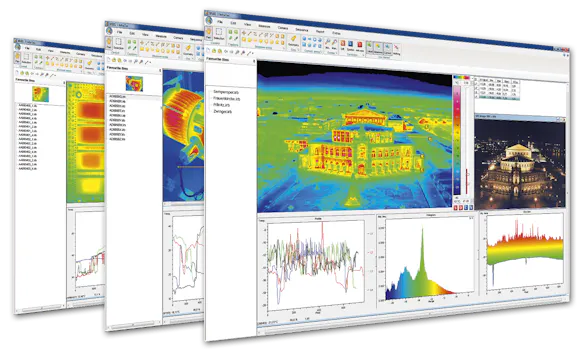

Fast and Detailed Analysis Using the Integrated IRBIS® 3 Software Package

The efficiency of an infrared camera significantly depends on its data analysis software. As a standard, the thermography software package IRBIS® 3 is included in each camera delivery. This software gives a fast, precise and detailed evaluation of obtained thermograms and sequences. With this, and the copy & paste function in all WINDOWS programmes a good basis is provided for comprehensive development work.

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Product Flyer

Get all the information you need at a glance in our product flyer

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.