ATEX

The most important basic principles on explosion protection can be found in the ATEX directives in relation to the European Union. The specifications for the protective housing of thermal imaging cameras and pan/tilt systems used in potentially explosive areas can be derived from this among other things.

Explosion protection plays an important role in many industrial branches today. Besides the chemical or mining industry, this also applies to large sections of the manufacturing industry. In the textile or timber industry there is often significant wear of materials, which can then become hazardous as dust. For this reason, protective measures are growing in significance for more and more plant operators. Solutions based on infrared thermography can offer additional safety here in hazardous areas.

Temperature as Safety-relevant Measurand

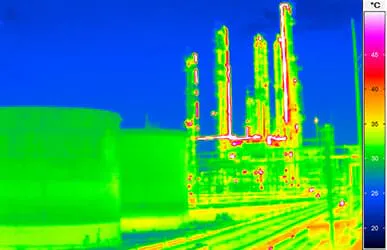

The distributions of surface temperatures for large-scale areas can be recorded with the aid of thermal imaging cameras. When integrated in a special protective housing, it is also possible to use the cameras in potentially explosive areas. ATEX-certified protective housings with pressure-resistant encapsulation are necessary for monitoring industrial processes or for early fire detection.

In numerous industrial environments the temperature in terms of plant safety is extremely important. On the basis of temperature values, it becomes apparent whether processes reach a critical state or benchmarks are exceeded. This all speaks in favour of continuous monitoring in these areas. An increased risk exists, for example, if an explosive gas-air mixture can result. Even the presence of dust is sufficient if this exists in a small grain size and appropriate density. Such substances can ignite easily. Often surfaces that are already hot, static electricity, mechanically generated sparks, glowing embers or electric arc cause an explosion.

The classification of the potentially explosive areas in regards to the ATEX directive indicates how great the risk of an explosion within which areas is.

Classification of Places where Potentially Explosive Areas May Occur (Ex Areas)

Potentially explosive places are classified in zones according to frequency and duration of the occurrence of potentially explosive atmospheres.

Source: Directive 2014/34/EU of the European Parliament and of the Council

Zone 0

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is present continuously for long periods or frequently.

Zone 1

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Zone 20

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, for long periods or frequently.

Zone 21

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

Zone 22

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

ATEX-certified Protective Housings and Pan/Tilt Systems from InfraTec

As a supplement to other monitoring systems, InfraTec offers thermographic systems that have ATEX-certified protective housings and pan/tilt systems. Depending on the requirement, these can be used in different protection zones for the gas and dust area. As components of a complete monitoring system for early fire detection, any number of thermal imaging cameras can be integrated into such a solution for the Ex area. Just one single thermographic camera provides a high degree of safety by combining it with images of a visual camera. This means that the monitoring of the plants in real time is achieved even in the most adverse visibility conditions involving smoke, fog, darkness or rain.

Consistent with the most diverse range of applications, InfraTec offers solutions with up to (1,024 x 768) IR pixels even for ultra-high resolution thermal imaging cameras. These systems can be equipped with a multitude of lenses, ranging from wide-angle lenses, telephoto lenses up to long-range zoom lenses. By combining these system components with very powerful software with extensive image-editing functions designed specially for these applications, large-scale areas and far distant objects can be monitored reliably and fully automatically.

ATEX-compliant Protective Housings and Pan/Tilt Systems are Used Here

Chemical industry

Refineries

Gas pipelines

Off-shore platforms

Gas flare monitoring systems

Textile industry

Timber industry

Background

ATEX is a name that originates from French and can be traced back to the term “atmosphères explosibles”. Two directives are currently summarised under the abbreviation – the ATEX Operational Directive 1999/92/EC as well as the ATEX Product Directive 2014/34/EU. Its validity is limited to the region of the European Union. In contrast, the US American Pendant, namely the National Electrical Code (NEC), is recognized internationally.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.