Thermography for Quality Assurance

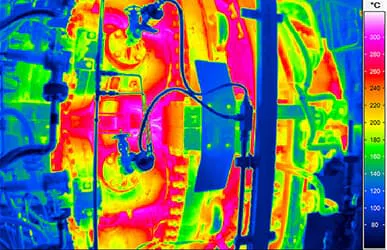

Today gas turbine power plants by the SIEMENS AG are more than ever complex high-tech products. They provide a continuous and reliable electrical power supply for industry and population worldwide. They do this using fossil fuels very efficient and therefore exceptionally friendly for our environment. To achieve this highest quality of every single component is absolutely imperative. Thus heavily stressed parts like the turbine blades are tested with the latest measurement techniques for example with infrared thermography.

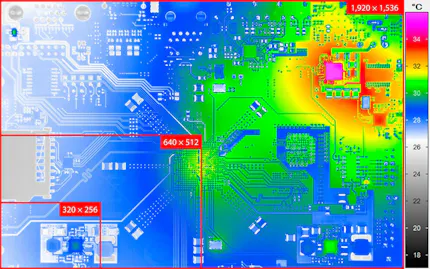

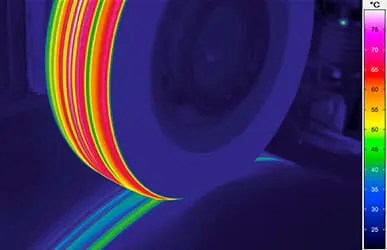

During the production of the turbine blades for gas turbine power plants the Siemens AG uses ceramic coatings since higher entry temperatures to the turbine blades are reachable which increases efficiency. Thereby it is necessary to ensure the correct application of the coatings with-out any losses at the flow channels. Mr. Sczepurek together with his team takes the responsibility for the required test techniques and processes. Out of the range of non-destructive testing methods he chose infrared thermography as it allows for checking large turbine areas particularly fast and reliable at the same time.

InfraTec Solution

SIEMENS AG

Energy Sector; Fossil Power

Generation Division

www.energy.siemens.com

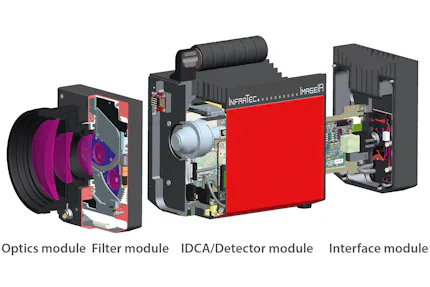

Infrared camera

ImageIR® 8300

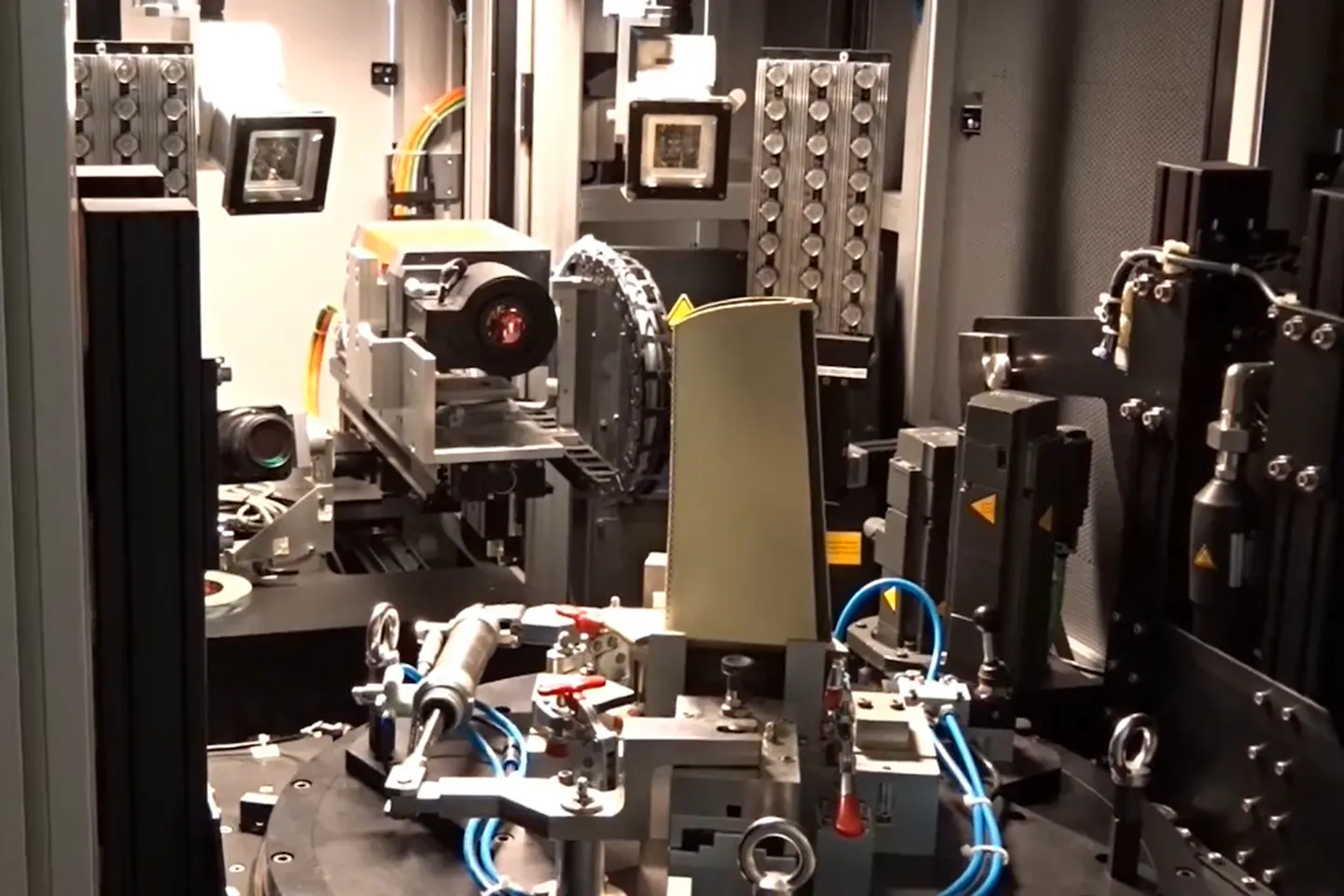

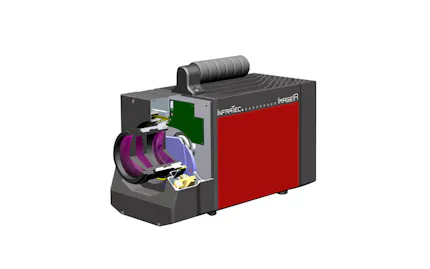

InfraTec supports this quality assurance by supplying high-performance and reliable infrared cam-eras from its own ImageIR® series manufactured in Dresden. The geometric resolution of 640 x 512 pixels being high for commercial, cooled thermal cameras provides together with a fast frame rate the necessary prerequisites to realize the test of every turbine reliably but also in eco-nomically justifiable time.

A fast motorized focussing as well as a data acquisition to the split milisecond and a camera control by a capable and cus-tomizable software of InfraTec also plays an important role. The flexible inter-face concept of the ImageIR® camera moreover allows for a seamless integration into the existing system environment. Additionally, the infrared cameras of the ImageIR® series can be combined with external excitation devices due to its precise trigger possibility. Thus, further parameters of turbine blades can be de-termined within the methodology of active heat flow thermography. Their analysis and practical ap-plication result in a further increase in efficiency for the customers of the gas turbine power plants of the SIEMENS AG.

Thermography for Quality Assurance for Turbine Blades