Active Thermography as a Process for Non-destructive Testing

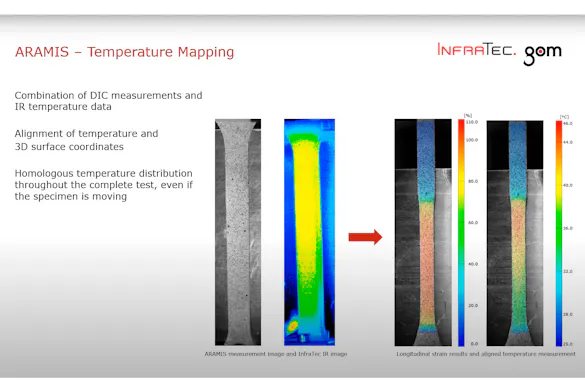

The essential feature of active thermography is the targeted supply of energy to the test object. A temporal and spatial characteristic heat flow results depending on the geometry and thermal properties of the test subjects. Its progression on the surface of the test object is captured by a thermographic camera.

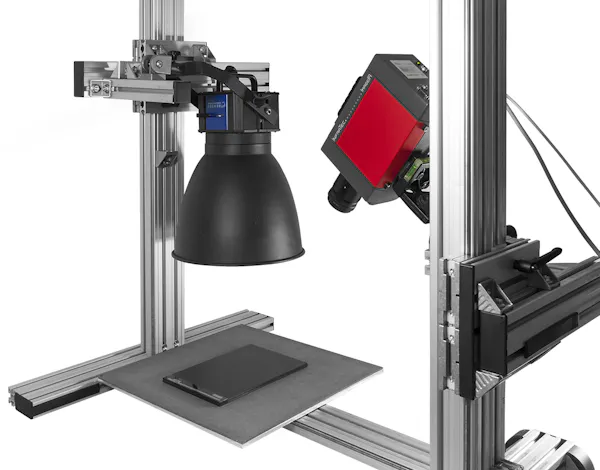

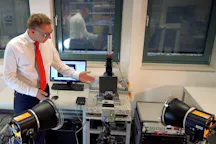

The cooled high-end camera series ImageIR® by InfraTec and uncooled microbolometer cameras of the latest generation of the VarioCAM® series by InfraTec are particularly suited for depicting the resulting temperature distributions. The geometric resolution of up to (2,560 × 2,048) IR pixels, high refresh rates as well as exact triggering and thermal sensitivity well below 0.015 K provide the technical requirement for detecting the smallest material defects.

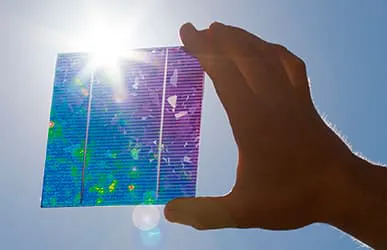

Rely on infrared thermography for non-destructive testing, benefit above all from the variable application of the process for different materials and material combinations. You can detect very different defects. This includes defects in joints, cavities, cracks or faulty joints. Thanks to such qualities, active thermography has firmly established itself as an efficient method for contactless and non-destructive testing in recent years.

You are looking for a new active thermography software or need new components or a replacement system for your thermosensorik system. If so, InfraTec is the right partner for you. We deliver universal & high-end solutions, a full service package and global sales and service to you.

More than 30 models: from uncooled infrared cameras to high-end IR systems for use in laboratory or in industryhandheld

Application-specific software packages enable precise and efficient data evaluation

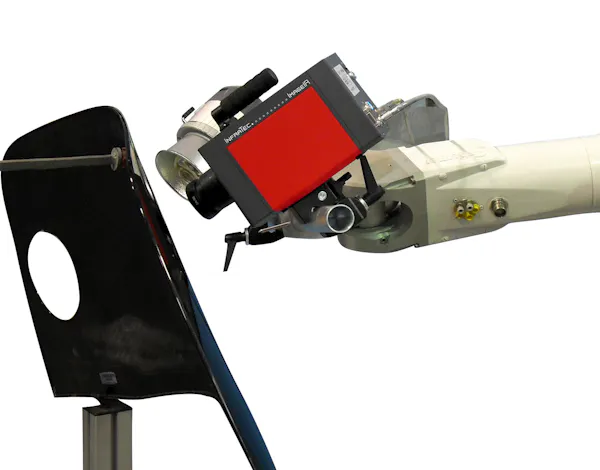

Turnkey thermographic automation solutions

Professional feasibility studies

Comprehensive range of services from 24-hour service hotline to extended warranties

First-class service ensures high system availability - worldwide sales + service

German designed, developed and manufactured - Made in Germany

Experienced sales and service partners enable local support levels

Do You Need New Components for Your Thermosensorik System?

If you are already using an active thermography system, for example from thermosensorik and need new components or a replacement system, then contact us.

Using Lock-in Thermography

Thermography for Non-destructive Material Testing

Efficient non-destructive testing of a wide variety of materials and defect types

Non-destructive testing saves time and costs

Analysation of process immanent temperature differences or externally induced heat streams

Pulsing activation allows the detection of below-surface errors

In-line applications for permanent quality control possible

Application Areas

Quality assurance for bonded, welded, soldered and other joints by means of cavity detections (e.g. on vehicle interior parts)

Detection of material defects in composites and cracks in metals

Quality assurance of intermediate products (e.g. layered compounds)

Localisation of defects in joints such as cavities, defective welding seams/points

Assessment of thermal cutting and injection processes

Testing of metallic and non-metallic materials/material compounds

Tests of internal structures, such as fractures or impacts in honeycomb lightweight constructions

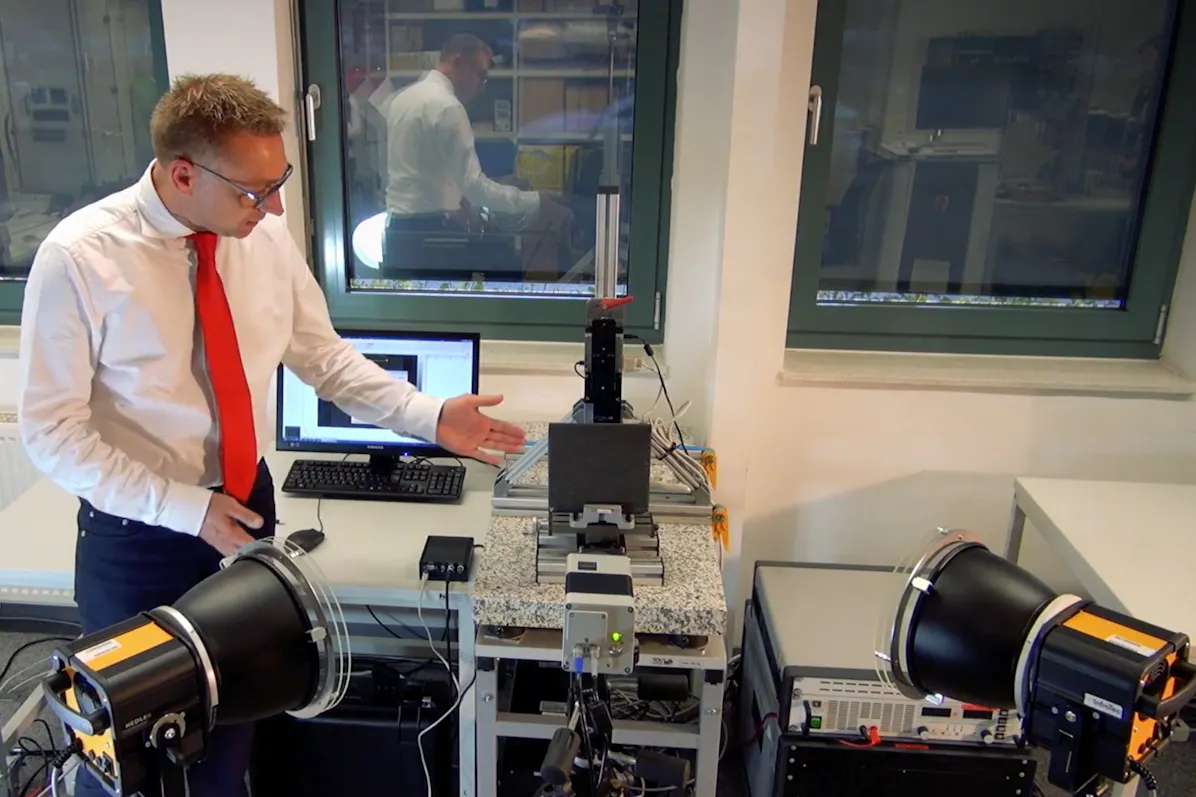

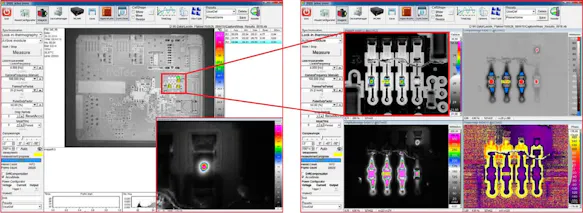

Modular Modular Thermography Test System Design for Precisely Fitting Inspections

The versatile application options of active thermography require an elaborate configuration of every single inspection system. InfraTec offers a wide variety of necessary components along with a modular system architecture. The high-resolution infrared cameras, efficient control and evaluation software as well as the continuously operable excitation sources and controllers are interchangeable within the system and therefore allow a flexible adaptation to upcoming requirements.

Benefits of the Modular High-end Test Systems

Online lock-in measurement with the highest sensitivity

Complete and detailed microscopy analysis

Geometrical resolution up to 1.3 μm per pixel with microscope lenses

Thermal resolution in the microkelvin range

Multi-layer analysis

Automatic scanning of larger samples due to precision mechanics

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.

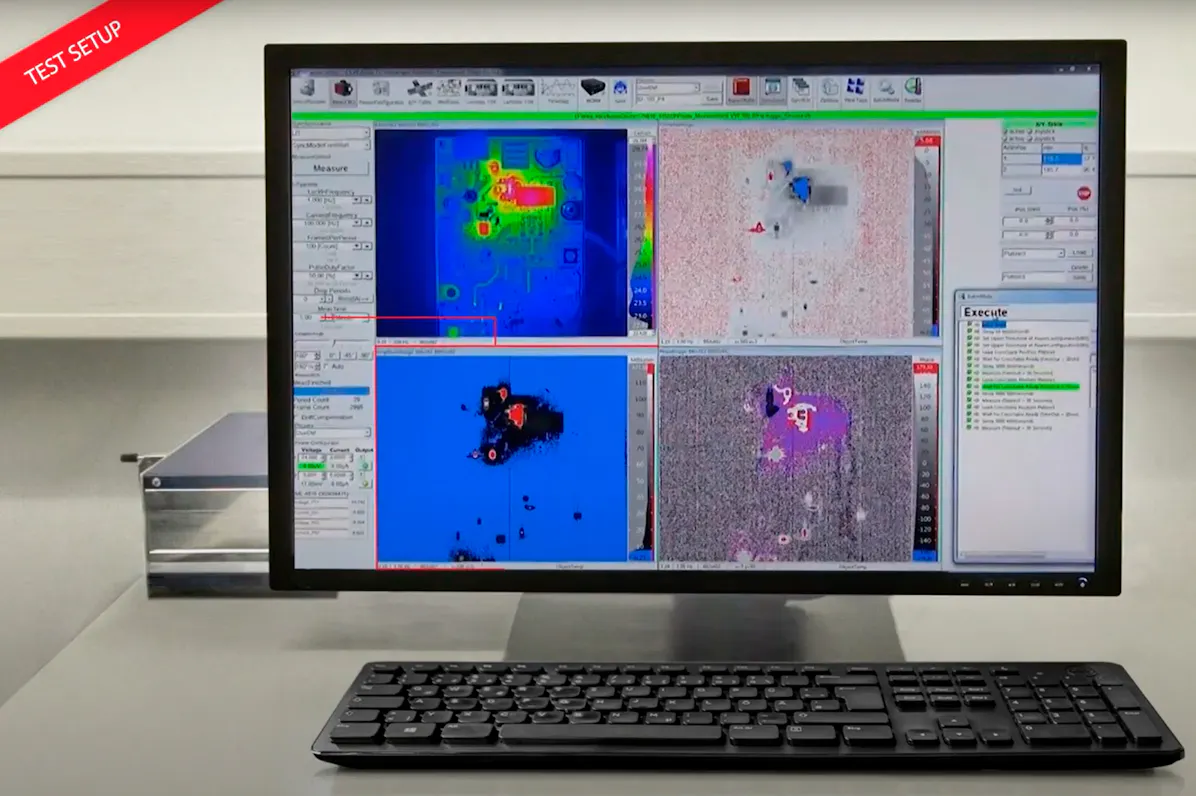

Efficient Control and Analysis Software for Active Thermography

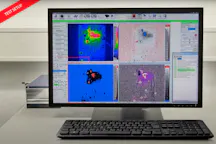

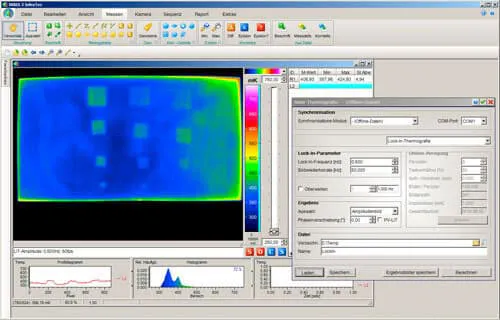

The thermography software IRBIS® 3 active analyses the thermo-graphic sequences, which have been generated during the test, and edits them to create a false colour image, in which defects can be marked for further evaluation or documentation. For this purpose, several different analysis procedures are available. The choice of the correct algorithm depends on the material characteristics, geometry and type of defects to be detected.

While the quotient method investigates the heat flow of the test object by reference to the increase and decrease of the surface temperature, the pulse-phase thermography (PPT) relies on the analysis of the temperature profile of different frequencies. For each frequency, two event images are generated, one amplitude- and one phase image. The lock-in thermography (LIT) analyses the sequence of periodic excitation of the test object.

Operational software with comprehensive analysis options in laboratory conditions

Software add-on for automatic error classification based on parameter settings

Intuitive user interface for easy operation

Real-time display of the object being measured in various states

Multifaceted memory options for image data and measurement results

Alternative 0°, 90° or customised set phase angle image for representation of complex intensity information

Merging live and amplitude image

Optional: IV measurement, under sampling, drift compensation, DC-mode, power loss measurement, user and protocol administration, interface preparation: e.g. Profibus, Ethernet

Do You Need New Components for Your Thermosensorik System?

If you are already using an active thermography system, for example from thermosensorik and need new components or a replacement system, then contact us.

InfraTec – Specialist for Infrared and Thermal Imaging Technology

InfraTec has been developing, producing and selling modern infrared technology for more than 30 years now. In addition to thermographic cameras, this includes turnkey thermographic automation solutions, infrared precision lenses, OEM components, software and a wide range of accessories. With more than 30 sales partners, the Dresden-based company is one of the world's leading suppliers of commercial thermography and thermal imaging systems. This enables customers to solve even the most demanding measurement and testing tasks in areas such as process optimization, quality assurance, research and development and material testing. In addition, InfraTec offers users a comprehensive range of services. This includes, for example, expert advice on the selection of technology, a calibration service and personnel training on the introduction of thermal imaging technology.

These Companies Use InfraTec Infrared Cameras