Current Appointments

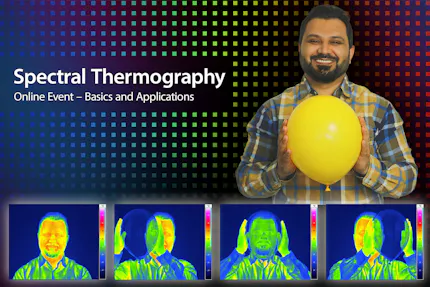

- Thermography for Industrial Automation (english)Virtual

Date

2025-06-24, 09:00 BST – 11:00 BSTRegister now

Quality Assurance at the Highest Level

Optimizing industrial processes is essential for companies that want to remain competitive in the long term. Increased productivity with the same or better quality and low costs can often be achieved through customized automation solutions.

When optimizing production processes, the recording of temperature and its progression often plays a crucial role. Conventional contact methods, however, rarely allow temperature deviations to be measured quickly and accurately enough without disrupting the process. Thermal imaging, a non-destructive testing method that can be customized for a wide variety of measurement tasks, has become an indispensable tool for quality assurance in serial production.

Thermal Imaging in Industrial Automation Offers Various Benefits, Including:

Fast, non-destructive control in a running process

Flexible adaptation to measurement tasks and specific needs

Evaluation and documentation using integrated software

Automatic triggering of follow-up processes

Versatile application options from cost-effective to highly precise

Thermography in Industrial Automation: Versatile and Flexible

Whether analyzing electronic and semiconductor components, measuring temperature distribution in hot-formed sheets or detecting the source of a fire in a warehouse at an early stage, thermal imaging can be used to detect small temperature differences up to a few millikelvins.

There are as many system solutions as there are individual measurement tasks. As the universally applicable system does not exist, we provide you with a modular system. This allows the selection of individual components, such as the infrared camera module with SDK, for example, or an individual, turnkey system solution can be put together for you by our colleagues. Based on specific examples, you will learn how our customers use these options.

Topics at a Glance

Thermography in industrial automation: potential and challenges

What is infrared radiation and how do infrared cameras work?

Software interface – results and insights from thermographic evaluations

Which InfraTec automated thermography solution is right for you?