Current Appointments

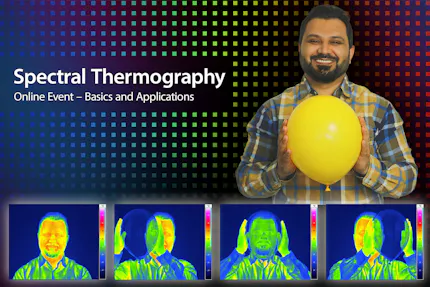

About the Online Event

The inspection of electronic components and assemblies by using active thermography is an established method for troubleshooting and quality assurance – from prototype development to series production.

In particular the lock-in thermography provides highly detailed information during each development step. This information can be essential for the design of complex electronic circuits or assemblies to optimise the thermal management. Active thermography is applied especially in electronics production as a versatile tool: for example, in quality assurance, for permanent monitoring of technological parameters as well as for inline inspection of products in manufacturing.

A Glimpse at the Online Event

Failure analysis and defect inspection

Quality and process control

Flexible R&D solution

Basic configuration to turnkey solution

Hotspot detection on printed circuit boards, integrated circuits, semiconductor material and multi-chip modules

Detection of faulty thermal connections of heat sinks, short circuits, soldering defects and wire bonding errors

Complementary Technical Lecture

We are pleased to announce a technical lecture from thermography practice:

Title: "Semiconductor IR-LIT Analytics – Challenges and Case Studies"

Speaker: Marko Hoffmann from Infineon Technologies Dresden GmbH & Co. KG